Table of Contents

Introduction

Robotics engineering in 2026 is no longer “just” about building cool machines – it is about building reliable, safe, intelligent systems that can work in messy real-world environments. Industry bodies are pointing to AI-driven autonomy and new application areas as major growth drivers for robotics, with industrial robot installation market value hitting an all-time high (US$16.7B) and 2026 trends emphasizing AI and autonomy and, expanding use cases. At the same time, employers increasingly view robotics and automation as a transformative force through 2030 – meaning demand is shifting toward engineers who can blend software, hardware, and systems thinking. This guide follows a practical skill structure – starting from core technical foundations (programming, math, electronics, mechanics), moving into robotics-specific depth (control, perception, simulation), and closing with the “career compounding” skills that keep you employable long-term.

New to Robotics? Start from the Basics. Join Now!

Ten Most Essential Skills

1) Proficiency in Programming Languages (and Robotics Software Stacks)

If robotics had a single “currency,” it would be software. You will write code that controls motors, processes sensor data, plans motion, avoids obstacles, and makes real-time decisions.

What to focus on

- Python for rapid prototyping, data pipelines, ML integration, and tooling.

- C++ for performance-critical components (real-time control loops, perception pipelines).

- ROS 2 as the dominant middleware direction: ROS 1 Noetic reached end-of-life on May 31, 2025, making ROS 2 skills more important for long-term maintainability and security.

Practical tip:

Don’t learn “languages” in isolation – learn how to ship working robot behaviours (drivers → perception → planning → control).

2) Strong Mathematics Foundation

Robots are physical systems operating in 3D space under uncertainty. Math is how you model that reality.

High-impact math areas

- Linear algebra (transformations, coordinate frames, state estimation)

- Calculus + differential equations (dynamics, motion, control responses)

- Probability and statistics (sensor noise, filtering, uncertainty-aware decisions)

Why it matters:

Without math, you can still build demos; with math, you can build systems that remain stable, accurate, and safe outside the lab.

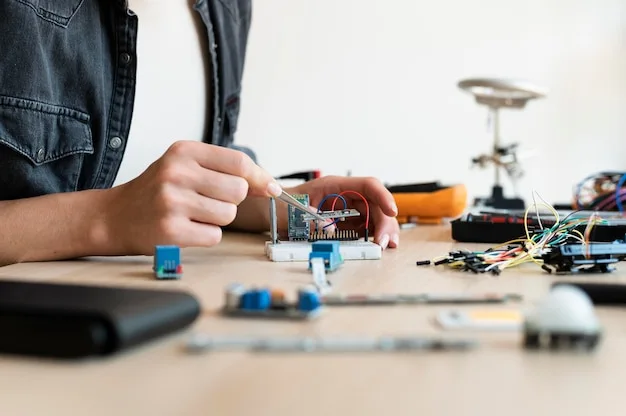

3) Electronics and Circuit Design Knowledge

Robotics fails in the real world for mundane reasons: noise, power instability, poor grounding, loose connectors, overheating. Engineers who understand electronics debug faster and design more reliable systems.

Key competencies

- Microcontrollers and embedded basics (Arduino, STM32, ESP32)

- Single-board computers (Raspberry Pi / similar)

- Power systems (battery selection, regulators, motor drivers, protection circuits)

- PCB fundamentals (even if you don’t design boards daily, you must understand how they behave)

This skill is central to integrating sensors/actuators without creating “mystery failures.”

4) Mechanical Engineering Principles

Robots are not only code – they are bodies that must move, carry loads, withstand vibration, and operate safely.

What you should be comfortable with

- Kinematics and dynamics (how motion is created and constrained)

- Materials and manufacturability (strength, weight, friction, fatigue, tolerances)

- Mechanisms (gears, linkages, belts, transmissions)

- 3D modelling (SolidWorks / Fusion / equivalents)

Mechanical literacy helps you design robots that can actually survive real usage—not just look good in CAD.

5) Control Systems Expertise

Control is where robotics becomes “robotics.” You can have excellent mechanical design and great code – yet still end up with shaky motion, overshoot, drift, and unsafe behaviour without strong control fundamentals.

Core topics

- Feedback loops and stability intuition

- PID control (tuning for real hardware conditions)

- State-space thinking (for more advanced systems)

- Trajectory tracking and precision motion

Control skills often separate hobby builds from professional-grade robots, especially in navigation and manipulation.

New to Robotics? Start from the Basics. Join Now!

6) Machine Learning and AI Basics

Modern robotics is increasingly shaped by AI – especially in perception (vision), decision-making, and adaptive behaviour. This is also consistent with industry’s push toward greater autonomy.

What “AI basics” should mean for a robotics engineer

- Understanding computer vision fundamentals (detection, segmentation, depth cues)

- Knowing when ML is appropriate vs. when classical methods are better

- Ability to use tools (PyTorch/TensorFlow) for inference and experimentation

- Comfort with deployment constraints: latency, compute limits, failure modes

AI should make your robot more robust, not more fragile.

7) Sensor Fusion and Perception Skills

Robots “understand” the world through imperfect sensors. Real autonomy depends on combining signals into a coherent, actionable view of the environment.

Key building blocks

- Working with cameras, LiDAR, depth sensors, IMUs, wheel odometry

- Calibration (a major real-world differentiator)

- Fusion and state estimation concepts (filters, localization pipelines)

- Mapping and environmental representation (when relevant)

Sensor fusion is one of the most employable competencies in robotics because it translates directly into field performance.

8) CAD and Simulation Proficiency

Great robotics engineers simulate early and often – because hardware iteration is expensive.

Tools and outcomes

- CAD for mechanical fit, packaging, and iteration

- Simulation environments (e.g., Gazebo-class tools) for virtual testing

- MATLAB/Simulink-style workflows for modelling and control exploration

- Scenario testing to find failures before the robot does

Simulation competence reduces cost, shortens dev cycles, and improves reliability.

9) Problem-Solving and Critical Thinking

Robotics is interdisciplinary debugging under pressure: sensors lie, motors saturate, timing breaks, and environments change.

What strong robotics problem-solving looks like

- Structured diagnosis (hypotheses → tests → measurement → iteration)

- Comfort reading logs, plots, and performance traces

- Thinking in systems: “If I change this parameter, what else breaks?”

- Designing for reliability (timeouts, watchdogs, fallback behaviours)

This is the skill that turns knowledge into shipped outcomes.

10) Collaboration and Continuous Learning

Robotics teams mix mechanical, electrical, embedded, ML, QA, product, and operations. You must communicate across disciplines and keep learning, because the stack evolves fast.

What to build here

- Clear documentation habits (diagrams, assumptions, interfaces, test notes)

- Ability to explain trade-offs to non-specialists

- Learning routines: projects, reading, community, conferences

- Staying current with major ecosystem shifts (e.g., ROS 2 direction after ROS 1 EOL)

A practical example: events like ROSCon (2025 was scheduled for Oct 27–29 in Singapore) help you track best practices and real-world adoption patterns.

New to Robotics? Start from the Basics. Join Now!

Key Takeaways

Robotics engineering thrives on a twisted blend of specialisation and broad knowledge – otherwise known as a “T-shaped” skill set. This hybrid approach lets you dig deep in one area with just enough knowledge of the rest to keep up with the breakneck pace of innovation in Industry 5.0.

Deep Strength in a Single Area of Expertise

Anchoring your skills in just one area like control systems will give you the precision stability you need to make a real impact. It is the same with perception for AI-driven sensing, embedded systems for merging hardware & software, motion planning for optimal pathways, manipulation for making dexterous grippers, or autonomy to make self-reliant decisions. This gives you the edge you need to be the go-to person on high impact projects – like surgical robots or warehouse automation.

Being a Jack of all Trades

You’ll also need to be pretty handy with the basics – like CAD & materials, circuits & sensors, and software like ROS, Python and machine learning algorithms. And that is the difference between being someone who just does the electronics and someone who can debug the bloody thing when it hits the wall. The key is to be the kind of person who can build a robot from the ground up.

Getting Good at Your Job

To take your skills from prototype to production ready, you need to get into good habits – like proper testing (unit/integration simulations), debugging (log analysis), documenting (version-controlled wikis), and collaborating with others (cross functional input). If you really want to make it in robotics, these are the things you need to be doing to get reliability – and to make sure your career doesn’t hit the buffers once the boom goes bust.

New to Robotics? Start from the Basics. Join Now!

Conclusion

By combining all the relevant skills with a clear and visible track record of success, you’re giving yourself a great chance of staying employed. And the potential for Industry 5.0 breakthroughs is huge. Everything applies from robots that can work alongside us humans to swarms of AI-driven machines that can revolutionise every business and every life. Get a foot in the door by taking some real-world, hands-on training now, and before you know it, you’ll be turning your ideas into working machines and shaping the world of tomorrow.

Frequently Asked Questions

What skills do I need to become a robotics engineer?

You need a blend of programming (Python/C++), math (linear algebra, calculus), electronics, mechanical basics, control systems, and perception – plus strong debugging and teamwork skills.

Which programming language is best for robotics engineering?

Start with Python for fast learning and prototyping, then add C++ for performance and real-time components. For robotics middleware, prioritize ROS 2.

Should I learn ROS 1 or ROS 2 in 2026?

Learn ROS 2. ROS 1 Noetic reached end-of-life on May 31, 2025, so ROS 2 aligns better with current and future industry needs.

Do I need to be strong in math for robotics?

Yes, especially linear algebra and probability. Math helps with motion, localization, sensor fusion, and control stability.

Is electronics mandatory for a robotics career?

If you want to work on real robots (not only simulations), electronics knowledge is a major advantage – power, wiring, microcontrollers, and sensor integration matter daily.