Table of Contents

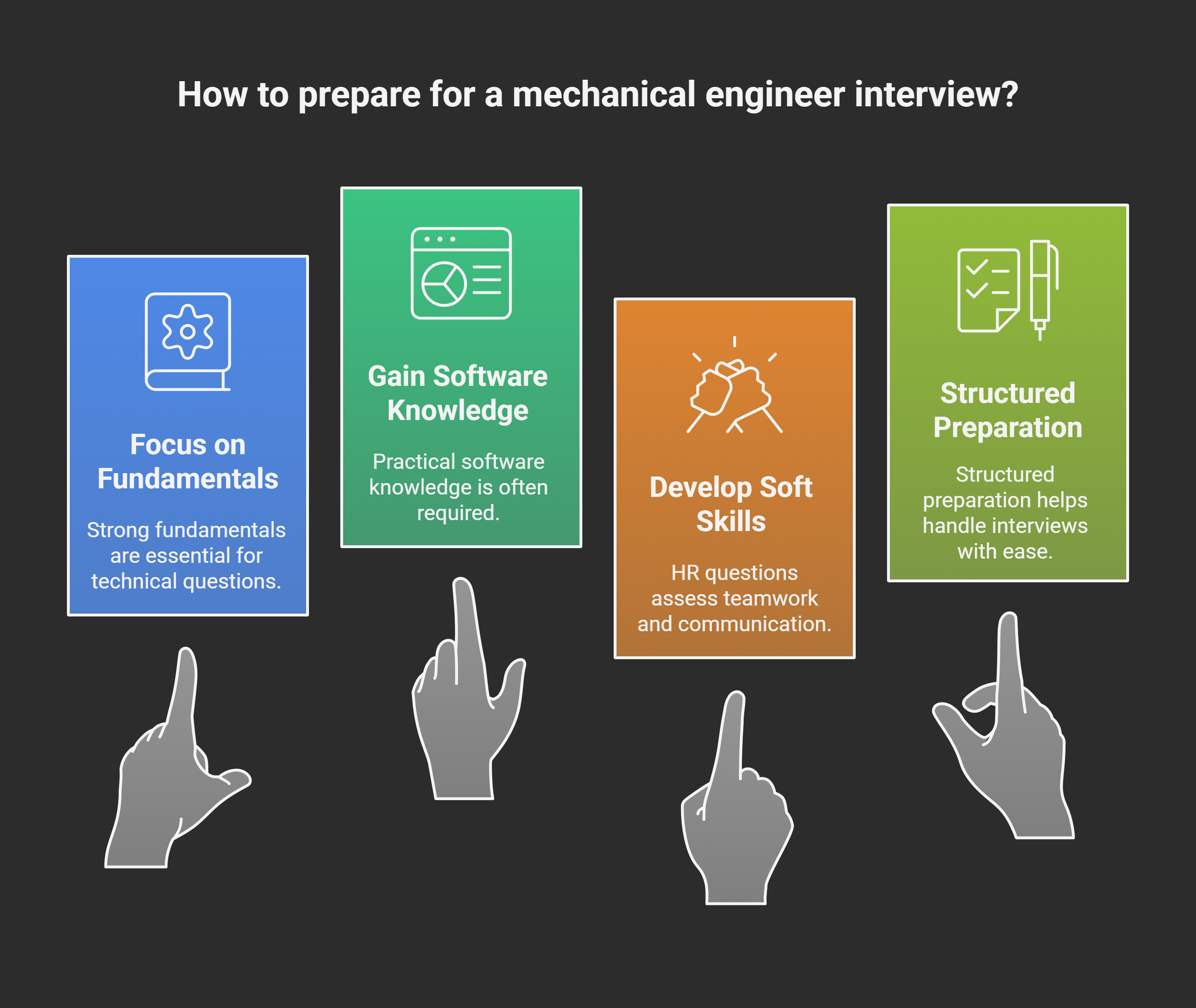

Many candidates search for Mechanical Engineer Interview Questions online. They test knowledge and real-world application skills. Interviewers often look for both theory and practice. Strong basics help interviewee answer technical questions confidently. Problem-solving ability is equally important during interviews. Employers see for clarity in explanations and reasoning. Preparing well helps in your chances of success.

These roles need technical and soft skills together. Interviews usually cover concepts, design, and practical problem solving. Candidates are asked about tools, materials, and processes. Knowledge of CAD and FEA is often checked. Employers also ask HR questions on teamwork and goals. A balanced preparation ensures confidence during interviews. Structured learning helps tackle questions effectively and calmly.

Key Takeaways

-

They test both theory and practice.

-

Strong fundamentals help in technical questions.

-

Practical knowledge of software is often essential.

-

HR questions assess teamwork and communication skills.

-

Structured preparation helps handle interviews with ease.

Get Career oriented MEP training with Expert Mentors! Get Free Demo Here!

Introduction

Mechanical engineering interviews need knowledge, confidence, and clear communication. Employers test both theory and practice during the process. Candidates face technical, design, and application-based questions regularly. Strong basics in laws and concepts create confidence. Practical knowledge of tools and software is equally tested. Interviewers often test through real-world problem-solving examples. A good preparation ensures better chances of success.

You must be prepared for diverse areas. Which include design, thermodynamics, mechanics, and manufacturing processes. Interviewers may ask about material properties and tolerance in design. Some focus on fluid mechanics and heat transfer applications. Software knowledge like CAD and FEA is often tested. Employers also evaluate communication and teamwork in HR questions. Confidence and clarity remain key for standing out.

What to Expect in This Blog

-

Fundamental concepts and laws

-

Design, materials, and manufacturing

-

Fluid mechanics and thermal engineering

-

Machine design and mechanics

-

Production, maintenance, and practical tools

Top 35 Mechanical Engineer Interview Questions and Answers

Master MEP Design with Industry-Leading Training!

Gain in-depth knowledge of Mechanical, Electrical, and Plumbing (MEP) Design with expert-led courses. Learn HVAC, fire safety, sustainable building strategies, and BIM applications to excel in the construction industry.

Know MoreFundamental Concepts & Laws

Q1. State and explain the First Law of Thermodynamics.

The First Law of Thermodynamics deals with energy conservation. It states energy cannot be created or destroyed. It can only change from one form to another. The internal energy of a system changes with heat. Work done by or on the system also matters. In simple form: ΔU = Q – W. This law is the foundation of thermodynamics.

Q2. What is Pascal’s Law and its application?

Pascal’s Law explains pressure distribution in fluids. It states pressure applied to fluid transmits equally. This is valid in all directions within the fluid. Hydraulic systems widely use this principle in practice. Examples include hydraulic lifts, jacks, and brakes. Small force applied creates large force output. This helps achieve mechanical advantage in machines.

Q3. Explain Hooke’s Law with practical importance.

Hooke’s Law describes the relation between stress and strain. It states stress is directly proportional to strain. This holds true within the elastic limit only. Beyond the limit, material deformation becomes permanent. The law is essential in spring design calculations. Engineers also use it for structural component analysis. It helps predict material response under load.

Q4. Define Newton’s Second Law of Motion.

Newton’s Second Law connects force, mass, and acceleration. It states force equals mass multiplied by acceleration. Mathematically, F = m × a. This law explains how objects respond to forces. It is the foundation of dynamics and motion analysis. Engineers use it to design moving machine parts. Examples include vehicles, robotics, and manufacturing systems.

Q5. Differentiate between stress and pressure.

Stress and pressure both involve force per unit area. Stress is internal resistance in materials under load. Pressure is external force applied on surfaces. Stress depends on material properties and geometry. Pressure depends on applied external force distribution. Stress occurs inside objects like beams or shafts. Pressure occurs in fluids, vessels, or air systems.

Q6. Explain reversible and irreversible processes in thermodynamics.

Reversible processes are ideal and perfectly efficient. They can reverse without energy loss or dissipation. Irreversible processes always involve friction, heat loss, or inefficiency. Most natural processes are irreversible in reality. Examples include combustion, heat conduction, and fluid flow. Engineers study reversible processes for theoretical analysis. Actual machines operate with irreversible behavior always.

Q7. What is the Zeroth Law of Thermodynamics?

The Zeroth Law defines the concept of temperature. It states if two bodies are in equilibrium. And both are in equilibrium with a third body. Then all three bodies share the same temperature. This principle enables construction of thermometers. It provides a measurable scale for thermal systems. Without it, temperature definition would not exist.

Design, Materials & Manufacturing

Q1. What factors affect material selection in mechanical design?

Material selection impacts strength, durability, and performance. Engineers consider several key factors before choosing a material.

-

Strength and toughness ensure load-bearing ability.

-

Hardness resists wear and surface damage.

-

Corrosion resistance improves long-term durability.

-

Cost and availability make the design feasible.

-

Weight and machinability affect efficiency and production ease.

A balance of all properties ensures safe, economical design.

Q2. What is the difference between ferrous and non-ferrous metals?

Ferrous metals contain iron as main component. They are magnetic and often prone to rust. Common examples include steel and cast iron. Non-ferrous metals do not contain significant iron content. They are lightweight and corrosion-resistant. Examples include aluminum, copper, and brass. Applications differ based on strength, weight, and corrosion needs.

Q3. Explain fatigue failure and its importance.

Fatigue failure occurs under repeated cyclic stresses. It can happen below the yield strength of material. Cracks develop slowly over repeated stress cycles. Eventually, sudden fracture occurs without prior warning. Fatigue is common in rotating and vibrating components. Examples include shafts, axles, and turbine blades. Engineers design with safety factors against fatigue failure.

Q4. Compare casting and forging processes.

Casting involves pouring molten metal into molds. It produces complex shapes with less machining. Forging deforms metal under compressive forces. It improves strength and grain structure significantly. Casting is economical for intricate designs. Forging is ideal for high-strength applications. Both processes are crucial in manufacturing industries.

Q5. Differentiate between brittle and ductile materials.

Brittle materials fracture without much deformation. Examples include glass and cast iron. They fail suddenly under stress conditions. Ductile materials deform before breaking. Examples include steel, copper, and aluminum. They absorb more energy before fracture. Engineers prefer ductile materials for safety-critical applications.

Q6. What is tolerance in engineering drawing?

Tolerance is the permissible variation in dimensions. It ensures parts fit and function correctly. Perfect manufacturing accuracy is never possible. Tolerance helps achieve interchangeability of components. It reduces production cost and saves machining time. Engineers specify tolerances based on function and application. Proper tolerancing ensures smooth assembly and operation.

Q7. Explain the concept of GD&T in design.

GD&T means Geometric Dimensioning and Tolerancing. It describes allowable variations in shape, orientation, and location. GD&T symbols standardize communication in engineering drawings. It ensures consistency between design, manufacturing, and inspection. Engineers use GD&T for higher precision. It helps avoid ambiguity in specifications. Industries rely on GD&T for global collaboration.

Q8. What is the significance of heat treatment in materials?

Heat treatment modifies properties of metals. It improves hardness, strength, and ductility. Common processes include annealing, quenching, and tempering. Annealing softens material and relieves stress. Quenching increases hardness by rapid cooling. Tempering reduces brittleness after quenching. Heat treatment extends material life and reliability.

Fluid Mechanics & Thermal Engineering

Q1. What is Bernoulli’s Theorem and its applications?

Bernoulli’s Theorem explains energy conservation in fluid flow. It states pressure, kinetic, and potential energies remain constant. This holds true along a streamline in ideal flow. Engineers apply this principle in nozzles and turbines. It also helps design aircraft wings and venturi meters. Real-world flows deviate due to friction losses. Still, Bernoulli’s Theorem is widely used in practice.

Q2. Define Reynolds Number and its significance.

Reynolds Number is a dimensionless quantity in fluid mechanics. It compares inertial forces to viscous forces in flow. The formula is Re = (ρVD)/μ. It determines whether flow is laminar or turbulent. Low Reynolds Number means smooth laminar flow. High Reynolds Number indicates turbulent chaotic flow. Engineers use it in pipeline and aerodynamics design.

Q3. What is cavitation in fluid machinery?

Cavitation occurs when pressure in liquid drops below vapor pressure. Vapor bubbles form and collapse violently in the fluid. This collapse causes noise, vibration, and component damage. Pumps, turbines, and propellers often face cavitation issues. It reduces efficiency and service life significantly. Designers prevent cavitation by maintaining required pressure levels. Proper design and maintenance minimize cavitation risks.

Q4. Differentiate between Otto cycle and Diesel cycle.

The Otto cycle is used in petrol engines. Heat addition occurs at constant volume conditions. Diesel cycle is used in diesel engines. Heat addition occurs at constant pressure conditions. Otto cycle provides higher efficiency at low compression ratios. Diesel cycle is efficient at high compression ratios. Both cycles form the basis of internal combustion engines.

Q5. What is entropy in thermodynamics?

Entropy measures disorder or randomness in a system. It represents unavailable energy for performing useful work. In real processes, entropy always increases. Reversible processes ideally maintain constant entropy. Irreversible processes involve entropy generation always. Engineers use entropy to study system efficiency. It is central to the Second Law of Thermodynamics.

Q6. Differentiate between heat engine and heat pump.

A heat engine converts heat into mechanical work. Examples include steam engines and IC engines. A heat pump transfers heat using external work. Examples include refrigerators and air conditioners. Heat engine efficiency depends on temperature difference. Heat pump performance is measured as coefficient of performance. Both devices follow thermodynamic principles but opposite goals.

Q7. Explain the concept of boundary layer in fluids.

Boundary layer forms when fluid flows over a surface. Fluid velocity is zero at the solid boundary. Velocity gradually increases until free stream value. Boundary layer causes frictional drag in fluid flow. Thicker boundary layers reduce efficiency of systems. Engineers study laminar and turbulent boundary layers. Controlling boundary layers improves aerodynamics and heat transfer.

Master MEP Design with Industry-Leading Training!

Gain in-depth knowledge of Mechanical, Electrical, and Plumbing (MEP) Design with expert-led courses. Learn HVAC, fire safety, sustainable building strategies, and BIM applications to excel in the construction industry.

Know MoreMachine Design & Mechanics

Q1. What is the factor of safety in design?

The factor of safety ensures reliability of machine components. It is the ratio of strength to actual applied load. Higher values provide greater safety margins. Designers choose it based on application and material. Critical systems like aircraft need higher safety factors. Less critical systems can use lower safety factors. It balances safety with cost efficiency.

Q2. Differentiate between static and dynamic loading.

Static loading applies a constant load over time. Dynamic loading varies with magnitude and direction. Dynamic loads often cause fatigue failures. Bridges, engines, and rotating shafts experience dynamic loads. Static loading is simpler to analyze mathematically. Dynamic loading requires detailed stress analysis methods. Engineers design differently based on loading conditions.

Q3. Explain different types of gears and their uses.

Gears transmit power between rotating shafts effectively. Spur gears have straight teeth and transmit quietly. Helical gears have angled teeth for smoother operation. Bevel gears transmit power between intersecting shafts. Worm gears provide high reduction ratios in compact form. Gear type selection depends on speed, load, and orientation. Proper gear design ensures efficient power transmission.

Q4. What is a flywheel and its purpose?

A flywheel stores rotational kinetic energy in machines. It maintains constant angular speed during cycles. Energy is stored when supply exceeds demand. Energy is released when demand exceeds supply. Engines use flywheels to reduce speed fluctuations. They also improve efficiency of mechanical systems. Without flywheels, machines may run unevenly.

Q5. Explain the concept of stress concentration.

Stress concentration occurs at points of abrupt geometry change. Examples include holes, notches, or sharp corners. Local stress increases significantly at these points. This weakens the component under load. Engineers reduce stress concentration using fillets and smooth curves. Proper design ensures longer component life. Ignoring it may lead to sudden failures.

Q6. What is the difference between keys and couplings?

Keys connect a shaft with rotating components. They transmit torque without slippage. Common types include square and woodruff keys. Couplings join two shafts for power transmission. They can be rigid or flexible in design. Couplings allow alignment and absorb shocks. Both ensure smooth mechanical power transfer.

Production & Maintenance

Q1. Explain preventive maintenance and its advantages.

Preventive maintenance involves scheduled inspections and servicing. It is performed before actual failure occurs. The goal is reducing breakdowns and downtime. Regular lubrication, cleaning, and calibration are common activities. Advantages include improved equipment reliability and longer service life. It reduces costly emergency repairs significantly. Preventive maintenance ensures smooth, safe industrial operations.

Q2. Differentiate between preventive and corrective maintenance.

Preventive maintenance is performed before failure happens. Corrective maintenance occurs after breakdown or defect. Preventive reduces unexpected downtime through regular care. Corrective restores function once equipment already fails. Preventive requires planning and scheduled inspections. Corrective is unplanned and sometimes costly. Both approaches are necessary in industries.

Q3. What is Total Productive Maintenance (TPM)?

TPM aims for zero breakdowns and zero defects. It involves all employees, from workers to managers. Key pillars include autonomous maintenance and continuous improvement. TPM increases productivity and equipment effectiveness. It focuses on reducing waste and downtime. It also enhances workplace safety and morale. Many industries adopt TPM for long-term efficiency.

Q4. Explain the concept of Lean Manufacturing.

Lean Manufacturing focuses on eliminating waste in processes. Waste includes defects, delays, and unnecessary movement. Lean uses principles like Kaizen and Just-in-Time. Benefits include higher productivity and lower costs. It also improves product quality and customer satisfaction. Employees play a major role in lean systems. Lean manufacturing strengthens competitiveness in industries.

Q5. What is Condition-Based Maintenance (CBM)?

CBM monitors equipment condition for maintenance decisions. Sensors track vibration, temperature, and lubrication status. Maintenance is done only when indicators show issues. This reduces unnecessary servicing efforts. CBM lowers maintenance cost compared to preventive methods. It extends equipment life through timely interventions. CBM requires investment in monitoring technology.

Software & Practical Knowledge

Q1. Which CAD software are commonly used in mechanical engineering?

CAD software helps create precise engineering drawings and models. Popular options include AutoCAD, SolidWorks, CATIA, and CREO. AutoCAD is widely used for 2D drafting tasks. SolidWorks is preferred for 3D design and assemblies. CATIA is used in aerospace and automotive industries. CREO is popular for advanced modeling and simulation. Software choice depends on project complexity and industry needs.

Q2. What is Finite Element Analysis (FEA)?

FEA is a numerical method for stress analysis. It divides structures into small finite elements. Mathematical equations solve stress, strain, and deformation values. Engineers use FEA to test designs virtually. It helps optimize material usage and safety factors. FEA reduces prototype requirements and development costs. It is essential in modern engineering design validation.

Q3. Explain Computer-Aided Manufacturing (CAM) and its benefits.

CAM uses computer software to control manufacturing equipment. It integrates directly with CAD design files. CAM automates machining processes like milling and drilling. Benefits include higher precision and reduced human error. CAM ensures faster production with consistent quality. It also reduces material waste during machining. Industries use CAM with CNC machines widely.

Q4. How important is simulation in mechanical engineering?

Simulation predicts performance before physical testing. It saves cost and time during design phase. Common simulations include thermal, structural, and fluid flow. Engineers optimize products without expensive prototypes. Simulation improves product safety and efficiency. It identifies potential failures early in design. Simulation is now integral to engineering projects worldwide.

Get Career oriented MEP training with Expert Mentors! Get Free Demo Here!

HR / Soft Skill-Based Questions

Q1. Why did you choose mechanical engineering as a career?

I chose mechanical engineering because of my interest in machines. From childhood, I enjoyed understanding how things work. Mechanical engineering combines creativity with strong analytical thinking. It allows solving real-world problems using practical solutions. This field offers opportunities across many industries worldwide. It also provides continuous learning and career growth potential. My passion for design and innovation drives this choice.

Q2. How do you handle teamwork challenges in projects?

Teamwork challenges arise due to communication gaps or conflicts. I handle them through open, respectful discussions always. Listening to every team member builds mutual trust. I focus on project goals instead of personal issues. If disagreements persist, I suggest practical compromises. Collaboration and empathy help resolve conflicts effectively. Strong teamwork ensures timely project completion with quality results.

Pro Tips for Interview Success

1. Revise Core Concepts

-

Review thermodynamics, mechanics, and material properties.

-

Focus on formulas and basic engineering laws.

2. Practice Practical Applications

-

Connect theory with real-world machine examples.

-

Explain projects showing practical applications clearly.

3. Improve Software Skills

-

Be confident using CAD, FEA, or CAM tools.

-

Highlight certifications or software project experience.

4. Prepare for HR Questions

-

Practice answers about teamwork and career goals.

-

Show clear communication and positive attitude.

5. Stay Calm and Confident

-

Listen carefully before answering questions.

-

Speak with clarity and avoid overcomplication.

-

Maintain professional posture and eye contact always.

Conclusion

Mechanical engineering interviews test theory, practice, and communication. Candidates must prepare across multiple subject areas. Strong basics create confidence during technical discussions. Practical knowledge shows ability to apply concepts effectively. Software skills highlight adaptability in modern engineering roles. HR answers reveal personality, teamwork, and leadership qualities. Balanced preparation improves overall interview performance.

Interviews reward clarity, confidence, and structured answers. Practicing questions builds speed and accuracy. Examples from projects strengthen technical explanations further. Preparation must include both technical and soft skills. Staying calm helps during difficult interview situations. Continuous learning ensures long-term success in mechanical careers. With effort, success becomes achievable for every candidate.

Master MEP Design with Industry-Leading Training!

Gain in-depth knowledge of Mechanical, Electrical, and Plumbing (MEP) Design with expert-led courses. Learn HVAC, fire safety, sustainable building strategies, and BIM applications to excel in the construction industry.

Know MoreFrequently Asked Questions

What topics are most important for a mechanical engineering interview?

Core concepts like thermodynamics, mechanics, and materials are key. Employers also test design knowledge, software skills, and practical applications. A balance of technical and soft skills is necessary.

How can I prepare effectively for technical questions?

Revise basic laws, principles, and definitions first. Practice solving problems from core subjects. Use examples from coursework or projects to explain.

Do interviewers ask about software tools?

Yes, knowledge of AutoCAD, SolidWorks, or Ansys is often expected. Employers value candidates who adapt to modern tools. Even basic understanding can create a positive impression.

How should I answer HR interview questions?

Be clear, honest, and confident in responses. Show teamwork, leadership, and problem-solving qualities. Use short, structured sentences for clarity.

What mistakes should I avoid in mechanical interviews?

Avoid giving vague or memorized answers. Never skip fundamentals while preparing. Don’t ignore communication and soft skills development.

Are practical examples important during answers?

Yes, practical examples strengthen your technical explanation. They show real application of theory. Examples make your responses more convincing.

How do I stay calm during tough questions?

Take a pause before answering. Break complex questions into smaller parts. Answer step-by-step to stay confident.

Can freshers crack mechanical engineering interviews easily?

Yes, with solid basics and practice, freshers succeed. Employers often value learning attitude more than experience. Confidence plays a key role.

Should I focus only on technical knowledge?

No, interviews check both technical and soft skills. Communication, teamwork, and adaptability are equally valued. Balanced preparation ensures better performance.

How does continuous learning help after interviews?

Continuous learning keeps you updated with new technologies. It improves long-term career growth. It also strengthens confidence for future interviews.