Table of Contents

The Difference Between MCB and MCCB confuses many beginners. Both devices appear similar at first. Their functions, however, are very different. People often mix them during selection. Understanding them helps prevent electrical accidents. Simple guidance makes electrical choices easier. Clear basics help everyone manage power safely. This topic is essential for new learners. Let’s explore these devices more clearly.

MCBs and MCCBs protect circuits from faults. Each device works best in specific situations. Right selection helps avoid equipment damage. Basic knowledge supports safer electrical usage. These concepts matter in daily setups.

Learning them boosts confidence in wiring decisions. Let’s continue with some key points.

Key Points

-

MCBs work for small electrical loads.

-

MCCBs handle larger and heavier loads.

-

MCBs have fixed trip settings.

-

MCCBs allow adjustable trip settings.

-

MCBs suit homes and small spaces.

-

MCCBs suit industries and large facilities.

-

MCBs are compact and easy to install.

-

MCCBs provide advanced protection features.

Get Career oriented MEP training with Expert Mentors! Get Free Demo Here!

Introduction

Electrical systems need safe and reliable protection devices. Two common devices are MCBs and MCCBs. Both protect circuits from dangerous electrical faults. They look similar but work very differently. Understanding them helps everyone make safer choices.

This blog explains these devices in simple words. It guides beginners with clear comparisons. It covers usage, features, and selection tips. Each section helps you learn step by step. Everything stays easy and practical for readers.

What This Blog Covers

-

Overview of MCB meaning and purpose.

-

Overview of MCCB meaning and purpose.

-

Key differences between both devices.

-

Common applications for each device.

-

Simple guidance for choosing the right breaker.

-

Main takeaways for quick revision.

-

Final conclusion for overall clarity.

What is an MCB?

An MCB is a protective electrical device. It helps stop damage from sudden electrical issues. The device works automatically during fault conditions. Its main purpose is ensuring safe circuit operation. People use it widely in many small installations. MCBs provide safety with simple and reliable action. Their design allows quick response to dangerous current. The device supports safe power use every day. This explanation helps you understand the device clearly.

An MCB replaces old fuse systems easily. It offers better safety than traditional fuse wires. The device restores power with a simple reset. It removes the need for replacing fuse parts. This feature saves time during electrical issues. MCBs help maintain consistent safety at home. They reduce fire risks from faulty circuits. People trust MCBs for their dependable performance. Their design supports long and stable operation.

Basic Working of an MCB

An MCB works through internal sensing parts. These parts detect abnormal current conditions quickly. The device cuts the circuit to prevent damage. This action stops high heat from harming wires. The working system depends on thermal movement. It also uses magnetic force for faults. Both systems operate automatically during unsafe events. These systems ensure fast protection every time. The working mechanism stays stable in daily use.

An MCB has two main internal actions. The thermal part handles slow overload issues. The magnetic part handles sudden short faults. Both parts work together for complete safety. The action remains smooth and reliable always. These parts function without user involvement. Users only reset after the fault clears. This system keeps the process simple overall. People appreciate this easy protective design.

Features of an MCB

1. Automatic Circuit Switching

-

MCBs switch off automatically during faults.

-

This action prevents dangerous current flow.

-

The switch restores by manual reset only.

2. Compact and Lightweight Structure

-

MCBs fit easily in small boxes.

-

Their design saves space in panels.

-

The devices stay lightweight for installation.

3. Reusable Protective Function

-

MCBs work repeatedly without replacements.

-

This makes maintenance simple and quick.

-

Users save money with reusable protection.

4. Clear ON and OFF Indication

-

MCBs show clear status positions visually.

-

This helps users understand device condition.

-

Indication supports safe power restoration.

Parts of an MCB

Important Components

-

Handle – allows manual operation safely.

-

Contacts – open or close power flow.

-

Trip Coil – senses sudden current issues.

-

Bimetal Strip – responds to slow overload.

-

Arc Chute – controls arc formation safely.

Supporting Components

-

Housing Case – protects internal components.

-

Terminal Screws – hold wires in place.

-

Operating Mechanism – manages switching actions.

Types of MCBs

MCBs come in different response categories. Each type suits specific current patterns. These types support different fault conditions easily.

Common Types

-

Type B MCB

-

Works for small household loads.

-

Trips quickly at low fault levels.

-

-

Type C MCB

-

Fits medium current loads comfortably.

-

Trips at moderate fault currents.

-

-

Type D MCB

-

Works for heavy starting loads.

-

Trips at high fault currents.

-

Advantages of Using an MCB

-

MCBs provide fast safety from faults.

-

They reduce risks of electrical fires.

-

The devices offer long service reliability.

-

Users reset them easily after issues.

-

MCBs require very low maintenance overall.

-

They provide safe performance every day.

-

Their design supports stable energy use.

-

People trust them for essential protection.

Simple Comparison Table

| Feature | Description |

|---|---|

| Full Name | Miniature Circuit Breaker |

| Main Use | Protects small circuits from faults |

| Reset Method | Manual reset required |

| Key Action | Automatic trip during faults |

| Construction | Compact and lightweight |

| Internal System | Thermal and magnetic action |

| Typical Range | Small current protection levels |

| Maintenance | Very low maintenance needed |

Summary

An MCB is a small protective switch. It helps stop unsafe current conditions fast. The device works automatically during faults. Its design supports simple and safe operation. People use it widely for daily electrical safety. Its parts ensure stable and reliable performance. Different types support different electrical patterns. Its advantages make it preferred everywhere. This overview explains its role clearly.

Master MEP Design with Industry-Leading Training!

Gain in-depth knowledge of Mechanical, Electrical, and Plumbing (MEP) Design with expert-led courses. Learn HVAC, fire safety, sustainable building strategies, and BIM applications to excel in the construction industry.

Know MoreWhat is an MCCB?

An MCCB is a strong protective device. It handles higher current levels safely. People use it for powerful electrical systems. The device stops faults before damage occurs. Its design supports stable and reliable protection. It works well in heavy-duty environments. This reliability makes it trusted by professionals. The device ensures strong safety during faults. This explanation helps you understand its purpose.

An MCCB can manage large electrical loads. It responds quickly to unsafe current levels. The device acts automatically during dangerous faults. Its structure controls heat and electrical stress. This protection helps maintain smooth operations. Users rely on it for consistent safety. Its design prevents system breakdowns effectively. The device supports safe power distribution. These features highlight its importance clearly.

Basic Working of an MCCB

An MCCB works through internal sensing systems. These systems watch current levels constantly. The device trips when readings become unsafe. This action protects circuits from major damage. It uses thermal action for overload issues. It uses magnetic action for fast faults. Both actions keep the device responsive. These systems operate without user involvement. Working remains stable in daily conditions.

An MCCB provides strong and fast responses. Its internal parts move during unsafe heat. Magnetic movement reacts to sudden surges. Both actions ensure full protective control. The device stops power immediately when needed. Its actions prevent overheating and fire risk. This function keeps systems running safely. Users reset the device after fault clearance. The system supports dependable daily operation.

Features of an MCCB

1. Adjustable Trip Settings

-

MCCBs allow changeable trip points.

-

Users set levels based on conditions.

-

This flexibility supports safer operation.

2. High Current Capacity

-

MCCBs handle large electrical loads easily.

-

They support heavy-duty environments smoothly.

-

Capacity stays stable in all situations.

3. Strong Protective Structure

-

MCCBs have powerful internal mechanisms.

-

The structure handles heat effectively.

-

Protection stays strong during faults.

4. Reusable Safety Design

-

MCCBs work repeatedly without replacements.

-

Users reset them after faults quickly.

-

Maintenance stays simple for years.

Parts of an MCCB

Main Components

-

Handle – allows manual device control.

-

Contacts – open and close circuit paths.

-

Bimetal Strip – handles overload protection.

-

Magnetic Coil – handles fast fault movement.

-

Arc Chamber – controls arc safely.

Supporting Components

-

Heavy Housing – protects internal systems.

-

Terminal Blocks – secure connecting wires.

-

Operating Mechanism – manages trip movement.

Types of MCCBs

MCCBs come in several design categories. Each type supports different load requirements. These types help match various power situations.

Common Types

-

Standard MCCB

-

Provides strong basic protection.

-

Works well in general settings.

-

-

High Breaking MCCB

-

Handles very high fault levels.

-

Fits powerful electrical environments.

-

-

Adjustable MCCB

-

Allows full trip adjustments.

-

Supports precise protection control.

-

Advantages of Using an MCCB

-

MCCBs support heavy electrical loads safely.

-

They offer powerful fault protection.

-

Trip settings allow flexible operation.

-

They reduce risks from intense faults.

-

Devices work reliably for many years.

-

Maintenance needs stay very minimal.

-

Their structure ensures high durability.

-

Professionals trust them for strong protection.

Simple Comparison Table

| Feature | Description |

|---|---|

| Full Name | Molded Case Circuit Breaker |

| Main Use | Protects large electrical circuits |

| Reset Method | Manual reset after fault |

| Key Action | Automatic trip during unsafe current |

| Construction | Strong and heavy structure |

| Internal System | Thermal and magnetic action |

| Current Range | Medium to high ratings |

| Maintenance | Low maintenance requirements |

Summary

An MCCB is a strong protective breaker. It manages high current levels safely.Its internal actions stop unsafe conditions fast. The device supports safe operation daily. Its parts ensure powerful protective action. Different types match different energy needs. Its advantages make it widely used. Professionals trust it for strong reliability. This overview explains its function clearly.

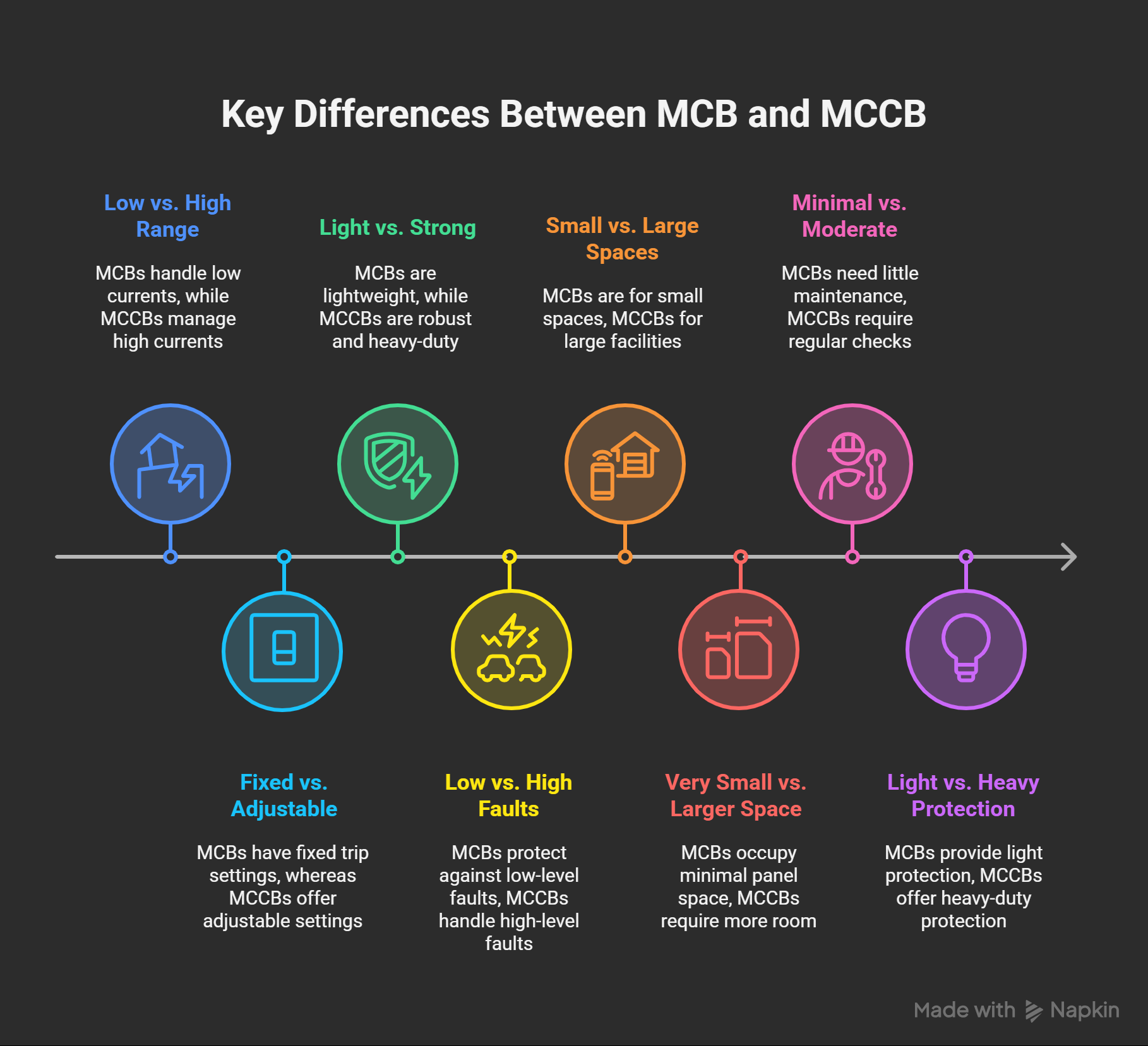

Key Differences Between MCB and MCCB

MCBs and MCCBs look similar at first glance. Their functions, however, differ in many important ways. Each device supports a different electrical environment. Their design also serves different safety needs. Understanding these differences helps avoid wrong selections. Simple clarity supports better electrical planning. Each difference reflects unique device behavior. These points help you understand them clearly. This section explains their differences in detail.

Many factors create important differences between MCB and MCCB. Working strength shows a major contrast between both devices. Internal systems operate in completely different ways. Breaking power also varies across these devices. Usage areas remain separate for each device type. Physical size adds another strong distinction here. Understanding these gaps supports correct electrical planning. Each difference directly affects overall performance. Clear knowledge helps avoid wrong selections.

Difference in Current Capacity

MCB Capacity

-

MCBs support small electrical loads.

-

Their current limits remain very low.

-

They fit light-duty setups easily.

MCCB Capacity

-

MCCBs support large electrical loads.

-

Their ratings reach very high levels.

-

They fit heavy-duty environments effectively.

Difference in Trip Settings

MCB Trip Nature

-

MCBs use fixed trip values.

-

Users cannot change these values.

-

They suit simple protective needs.

MCCB Trip Nature

-

MCCBs allow adjustable trip controls.

-

Users can set desired trip points.

-

They support precise protection adjustments.

Difference in Structural Strength

MCB Structure

-

MCBs have lightweight construction.

-

Their body suits small installations.

-

Their parts handle limited stress.

MCCB Structure

-

MCCBs have strong, heavy designs.

-

Their structure handles high stress.

-

Their parts support tough conditions.

Difference in Breaking Capacity

MCB Breaking Ability

-

MCBs handle small fault currents.

-

Their breaking power stays low.

-

They suit low-risk conditions.

MCCB Breaking Ability

-

MCCBs manage large fault currents.

-

Their breaking power stays high.

-

They suit high-risk environments.

Difference in Usage Areas

MCB Usage

-

MCBs support homes and small spaces.

-

They work well with small circuits.

-

Their use stays mostly domestic.

MCCB Usage

-

MCCBs support large power systems.

-

They work in demanding environments.

-

Their use stays mostly industrial.

Difference in Maintenance Needs

MCB Maintenance

-

MCBs need very little attention.

-

Their components work smoothly daily.

-

Repairs remain rare and simple.

MCCB Maintenance

-

MCCBs need occasional inspection routines.

-

Their systems require careful monitoring.

-

Maintenance supports long-term reliability.

Difference in Size and Form

MCB Size

-

MCBs remain small and compact.

-

They fit easily in tiny panels.

-

Their size supports easy installation.

MCCB Size

-

MCCBs remain bigger and heavier.

-

They need more panel space.

-

Their size suits heavy installations.

Simple Comparison Table

| Feature | MCB | MCCB |

|---|---|---|

| Current Capacity | Low range | High range |

| Trip Settings | Fixed | Adjustable |

| Structure | Light | Strong |

| Breaking Capacity | Low faults | High faults |

| Usage Area | Small spaces | Large facilities |

| Panel Space | Very small | Larger space |

| Maintenance | Minimal | Moderate |

| Typical Purpose | Light protection | Heavy protection |

Summary

MCBs and MCCBs differ in many key areas. Capacity levels show clear separation between both devices. Trip systems function in completely different ways. Construction strength creates another major contrast here.

Usage conditions also vary across both options. Maintenance needs show noticeable differences too. Breaking abilities remain highly distinct in comparison. Each point highlights unique protective behavior. This summary gives a clear overall understanding.

Get Career oriented MEP training with Expert Mentors! Get Free Demo Here!

Applications of MCB and MCCB

MCBs and MCCBs support many electrical setups effectively. Each device fits different safety conditions easily. Their use depends on load size and environment. Both devices help maintain safe electrical operation. Many installations depend on them for protection. Understanding these applications supports better planning. Clear ideas help users choose correctly. These points explain their common usage. This section gives complete clarity on applications.

MCBs usually support small electrical systems safely. They fit simple circuits with light power loads. MCCBs work with larger installations requiring strong protection. They suit heavy power demands and rough conditions. Both devices work widely in daily environments. Users pick them based on electrical needs. Each device ensures safe energy flow everywhere. These applications reflect different protection levels. This helps you match devices correctly.

Applications of MCB

MCBs serve many small and medium setups. They work well in places needing simple protection. Their compact size suits small wiring arrangements. They offer safe performance for everyday users.

1. Household Electrical Circuits

-

Used in basic home wiring lines.

-

Protect lighting circuits from overloads.

-

Support safe protection for daily appliances.

2. Small Commercial Spaces

-

Used in shops with low load levels.

-

Protect billing systems and small machines.

-

Keep small offices safe from faults.

3. Educational Buildings

-

Used in schools with simple circuits.

-

Protect lights and projectors effectively.

-

Keep classroom devices safe from damage.

4. Control Panels

-

Used in small control units.

-

Protect switches and control gear.

-

Support simple automation setups safely.

5. Temporary Installations

-

Used for exhibition setups easily.

-

Provide quick safety without complexity.

-

Fit small portable panels comfortably.

Applications of MCCB

MCCBs serve environments needing strong protection. They work well with high current loads. Their design suits demanding electrical systems. They maintain safety during heavy energy usage.

1. Industrial Power Distribution

-

Used in factories with huge loads.

-

Protect motors and production machines.

-

Support continuous high-power operations.

2. Large Commercial Buildings

-

Used in malls with heavy energy demand.

-

Protect escalators and cooling units.

-

Support stable supply for large loads.

3. Utility Power Systems

-

Used in main distribution sections.

-

Handle major supply lines safely.

-

Support long working hours daily.

4. Backup Power Systems

-

Used with generators of high capacity.

-

Protect generator output lines effectively.

-

Support safe switching during failures.

5. Heavy Equipment Protection

-

Used in cranes and compressors.

-

Protect high-torque machines quickly.

-

Maintain safe operation under pressure.

Shared Applications

Both devices support safe circuit performance. They help prevent major electrical failures. Both ensure smooth operation during unexpected faults. These uses show their protective value everywhere.

Common Areas

-

Panels – manage fault protection reliably.

-

Workshops – support different tool loads.

-

Public Buildings – ensure safe electrical flow.

-

Power Rooms – maintain system stability.

Application-Based Comparison Table

| Area | MCB Application | MCCB Application |

|---|---|---|

| Homes | Lights, fans, outlets | Not typically used |

| Small Offices | Computers, printers | Medium machines |

| Large Buildings | Small circuits only | Entire building loads |

| Industries | Light machines | Heavy machinery |

| Generators | Small backups | Large generator lines |

| Panels | Small control panels | Large power panels |

| Workshops | Small tools | High-power tools |

| Public Areas | Basic circuits | Main supply sections |

Factors Affecting Application Choice

Application choice depends on several conditions. Load level plays the biggest role here. Fault risk also influences device selection. Space availability affects final decisions. Required durability also guides usage choices. These factors shape the correct application. Clear understanding supports safer selection. Each environment needs specific protective strength. These points help you plan correctly.

Summary

MCBs serve small loads and basic environments. They support homes, offices, and simple systems. MCCBs serve heavy loads and tough conditions. They support industries, panels, and major buildings. Each device fits unique working situations well. Understanding applications guides safer decisions. Correct usage protects circuits effectively. Each setup needs different protective strength. This section explains these applications clearly.

Master MEP Design with Industry-Leading Training!

Gain in-depth knowledge of Mechanical, Electrical, and Plumbing (MEP) Design with expert-led courses. Learn HVAC, fire safety, sustainable building strategies, and BIM applications to excel in the construction industry.

Know MoreHow to Choose Between MCB and MCCB

Choosing the right breaker needs clear understanding. Each device suits specific working conditions better. Selection depends on load size and environment. The right choice avoids electrical accidents easily. Good decisions help systems work smoothly daily. Understanding key factors supports correct selection. This section explains those factors simply. Each point guides you toward safe decisions. Clear guidance helps beginners select confidently.

Both devices work well in suitable situations. Wrong selection can cause major safety issues. Correct planning reduces risks from heavy loads. Different applications need different breaker strengths. Following simple steps ensures better selection. Each step supports safe electrical performance. Good knowledge leads to safer installations. These ideas keep your system protected.

1. Check the Load Level

Load level guides basic breaker choice. Small loads fit MCBs more easily. Large loads demand MCCB protection instead. Correct load match prevents unnecessary tripping.

Note

-

Understand total connected load clearly.

-

Check peak load during heavy usage.

-

Compare load with breaker rating.

2. Identify the Fault Risk

Fault risk varies in different places. Areas with heavy machinery show higher risk. Smaller setups show lower fault levels. Choose a breaker that handles expected faults.

Note

-

Check short-circuit risk accurately.

-

Study past fault patterns if available.

-

Use stronger breakers for higher risk.

3. Evaluate Protection Needs

Protection needs differ across environments. Basic protection works well in simple systems. Advanced protection suits heavy environments better. Choose a device with matching protection strength.

Note

-

Decide if adjustments are required.

-

Check response speed requirements carefully.

-

Choose stable protection for sensitive equipment.

4. Consider System Size

System size influences breaker selection. Small circuits fit compact breakers easily. Large circuits need stronger and bigger units. Space planning supports smooth installation work.

Note

-

Measure available panel space clearly.

-

Check wiring arrangement before selection.

-

Fit breakers comfortably within panel limits.

5. Review Durability Needs

Some systems run for longer hours. Such systems need highly durable protection. Light systems need moderate durability only. Choose the device matching your usage period.

Note

-

Check required operating hours daily.

-

Choose sturdy breakers for long operation.

-

Select simple breakers for light usage.

6. Study Maintenance Requirements

Maintenance also affects breaker choice. Some environments allow regular inspection easily. Others need low-maintenance protection instead. Pick devices matching your maintenance ability.

Note

-

Check available maintenance support nearby.

-

Choose durable breakers for tough places.

-

Pick simple systems for easy handling.

7. Look at Budget Limits

Budget influences final decisions clearly. MCBs cost less for small needs. MCCBs cost more for heavy uses. Choose options matching your financial plan.

Note

-

Set a clear budget early.

-

Compare prices before selecting.

-

Pick the safest option within limits.

Simple Selection Table

| Factor | Choose MCB When | Choose MCCB When |

|---|---|---|

| Load Level | Load is small | Load is large |

| Fault Risk | Risk is low | Risk is high |

| Protection Need | Simple response needed | Advanced response required |

| Panel Space | Space is limited | Space is ample |

| Durability | Light use expected | Long use expected |

| Maintenance | Frequent checks easy | Tough areas need strength |

| Budget | Low budget planned | Higher budget possible |

Summary

Selecting the right breaker needs clear judgment. Load level creates the biggest difference here. Risk level also guides proper selection. System size strongly affects breaker choice. Durability needs shape final decisions too. Maintenance ability supports smarter choices. Budget limits also influence device selection. Each factor helps you choose wisely. This section provides simple selection guidance.

Key Takeaways

-

MCBs suit small and simple circuit needs.

-

MCCBs suit heavy and complex electrical networks.

-

Load size guides the correct breaker choice.

-

Fault levels influence final breaker selection.

-

MCBs offer fixed and simple trip functions.

-

MCCBs support wide and adjustable trip settings.

-

MCBs fit small panels with limited space.

-

MCCBs require larger and stronger panel areas.

-

Environment conditions affect breaker selection strongly.

-

Budget differences matter during final planning.

-

Maintenance needs differ between both devices.

-

Homes depend mostly on MCB protection.

-

Industries rely greatly on MCCB strength.

-

Choosing right improves system safety greatly.

-

Proper selection prevents serious electrical failures.

Conclusion

Electrical safety improves with correct breaker selection. Every system needs protection based on real load. Clear understanding supports safer installation decisions. Each breaker offers unique strengths for users. This helps reduce faults in daily operations. Knowing the Difference Between MCB and MCCB supports clarity. Such clarity makes planning easier for everyone. Smart selection ensures long-term electrical stability.

Choosing the right device avoids major electrical risks. Small systems benefit from lightweight protection choices. Large setups need stronger breakers for safety. Proper evaluation helps match system conditions well. Good planning prevents sudden power failures easily. Regular checks also improve protection reliability. Every network should follow safe breaker practices. Strong decisions ensure dependable system performance.

Master MEP Design with Industry-Leading Training!

Gain in-depth knowledge of Mechanical, Electrical, and Plumbing (MEP) Design with expert-led courses. Learn HVAC, fire safety, sustainable building strategies, and BIM applications to excel in the construction industry.

Know MoreFrequently Asked Questions

What is the main purpose of an MCB?

An MCB is mainly used to protect small electrical circuits from overloads and short circuits. It automatically trips when the current exceeds the safe limit, preventing damage to wiring and appliances. MCBs are most commonly used in homes, small offices, and low-load distribution boards.

What is the main purpose of an MCCB?

An MCCB protects larger circuits that carry higher current levels and require adjustable protection. It handles heavy loads, stronger fault currents, and more demanding industrial environments. MCCBs are used in factories, commercial buildings, and large electrical networks.

How does an MCB differ from an MCCB?

The key differences lie in current capacity, adjustability, and application areas. MCBs handle smaller loads with fixed trip settings, while MCCBs handle higher loads with adjustable trip functions. MCCBs also offer better fault-handling capabilities suitable for industrial systems.

Which device is better for home electrical systems?

MCBs are generally the best choice for home electrical systems because household loads are small and steady. They provide fast protection, are easy to reset, and fit well into compact home distribution boards. MCCBs would be unnecessary and oversized for regular household wiring.

When should I choose an MCCB instead of an MCB?

You should choose an MCCB when dealing with high-current circuits, industrial machines, heavy commercial loads, or systems requiring adjustable trip settings. MCCBs are also necessary when the fault level is high or when the environment is harsh.

Are MCBs and MCCBs interchangeable?

They are not interchangeable because they serve different power levels and protection needs. Replacing an MCCB with an MCB in a high-load environment can cause severe electrical hazards. The reverse substitution wastes capacity and space without providing additional benefit.

Can both MCB and MCCB protect against short circuits?

Yes, both can protect against short circuits, but their capacities differ significantly. MCBs handle lower short-circuit levels suitable for light circuits, while MCCBs manage much higher short-circuit currents found in industrial networks. MCCBs also allow advanced trip settings for precise protection.

Which breaker type is easier to maintain?

MCBs are easier to maintain because they have a simple construction and fixed settings. MCCBs require more technical handling, including periodic testing and sometimes calibration. Industrial environments generally have trained technicians for MCCB maintenance.

Does panel space affect the choice between MCB and MCCB?

Yes, panel space is an important factor because MCBs are smaller and fit compact boards, while MCCBs are bulkier and require larger panels. A small distribution board cannot accommodate large MCCBs. Space planning is essential before final selection.

How do I know which breaker is right for my application?

You should evaluate load size, fault levels, environment conditions, trip setting needs, panel space, and maintenance capabilities. Small circuits work best with MCBs, while large or industrial circuits require MCCBs. If unsure, consulting a qualified electrical professional ensures safe and accurate selection.