Table of Contents

The successful completion of any construction or engineering project would not be complete without the indispensable role of an MEP Quantity Surveyor. To clarify, MEP is an acronym that stands for Mechanical, Electrical, and Plumbing. These are the basic systems that make a building or other infrastructures function efficiently, ensuring the safety and comfort of its occupants. The systems are usually complicated and would require intensive planning, execution, and financial management. This is where an MEP Quantity Surveyor comes into play-the person who acts as a bridge between engineering and financial management to ensure that MEP projects are completed on time, within budget, and of the highest quality.

Get hands-on with our MEP Quantity Surveyor course – sign up for a free demo!

This blog post discusses the significance of MEP quantity surveyors along with their key roles and responsibilities, what skills are needed to excel in the profession, as well as the answers to the most frequently asked questions. When you finish reading this article, you will know everything about why this position is important in the construction industry.

Importance of an MEP Quantity Surveyor

A myriad of systems will keep any given building alive. Be it functioning efficiently, conserving energy, or providing and maintaining safety for its inhabitants, the premises will largely depend on the MEP systems. The complexity of the MEP systems requires specialized contractors to design, install, and maintain them. Therefore, it makes it extremely difficult to manage costs and oversee finances. This is where the role of the MEP Quantity Surveyor comes into play, a professional specialized in the financial and contractual management of MEP projects.

The existing potential of an MEP Quantity Surveyor cannot be underestimated. They are the key players in:

- Cost Management: MEP Systems, like plumbing, electrical, and mechanical installations, also take away the bulk of a project budget. They will ensure that cost estimates are accurate and monitored throughout the project lifecycle so that they are well controlled, complemented by the presence of MEP Quantity Surveyors.

- Optimized Resource Use: A properly analyzed and interpreted project requirement allows every function of an MEP Quantity Surveyor to include efficient usage of materials, labour, and equipment with no waste and expenses involved in usage.

- Quality Control: The industry put up stringent standards that an MEP system must follow. Hence, MEP Quantity Surveyors are responsible for ensuring that all works done are compliant; thus, avoiding the rework and expense involving legal issues.

- Onset Deadlines: Any delay in MEP installation can affect the whole project. An MEP Quantity Surveyor schedules these works through proper budget handling and contracts.

- Risk Management: Building sites are in born nature risky, exposing the projects to cost overruns, delay, and dispute risks. The MEP quantity surveyor undertakes diagnosis and mitigation of these risks in order to facilitate smooth execution of the project.

Without the expertise of an MEP Quantity Surveyor, projects could face significant financial and operational challenges, ultimately impacting their success.

Get hands-on with our MEP course – sign up for a free demo!

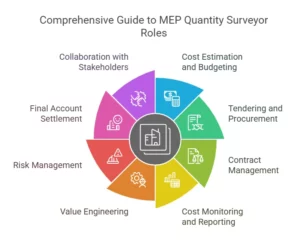

MEP Quantity Surveyor : Key Roles and Responsibilities

The work of an MEP quantity surveyor encompasses the technical and financial managerial aspects of his profession. Following are the major functions an MEP quantity surveyor has to perform:

1. Cost Estimation and Budgeting

- Before commencing a project, an MEP quantity surveyor prepares his detailed cost estimates for all MEP systems, namely, those related to mechanical, electrical, and plumbing components.

- Finally, they prepare a complete budget that is matched with client monetary expectations and project strings.

2. Tendering and Procurement

- An MEP Quantity Surveyor compiles tender documents and tenders to call for bids from contractors and suppliers.

- He/she evaluates the bids according to cost, quality, reliability, etc., to decide on the selection of the vendor.

3. Contract Management

- Preparation, review, and administration of contracts are core responsibilities. An MEP Quantity Surveyor will check the clarity and fairness of all contract terms and conditions.

- They monitor contractor performance with respect to contractual obligations.

4. Cost Monitoring and Reporting

- An MEP Quantity Surveyor will monitor spends with comparison to the budget through the building project.

- They also provide frequent financial data reports to stakeholders indicating divergence and potential remedies.

5. Value Engineering

- An MEP Quantity Surveyor recognizes cost-saving opportunities while ensuring the quality or performance is not jeopardized.

- They do this by providing inputs for alternative materials methods or designs for more cost-effective applications.

6. Risk Management

- Potential financial and operational hazards of the project are noted primarily by the MEP quantity surveyor.

- They formulate a risk mitigation strategy that guarantees that the project will not deviate from its plan.

7. Final Account Settlement

- An MEP Quantity Surveyor evaluates and finalizes all accounts at the close of a project.

- He reconciles financial disputes and claims, in order that all are contented in the end.

8. Collaboration with Stakeholders

However, an MEP quantity surveyor works closely with architects, engineers, contractors, and customers to align the financial contracts of the parties involved.

These depend primarily on the MEP quantity surveyor among the multiple parties for any communications facilitation.

Master MEP Design with Industry-Leading Training!

Gain in-depth knowledge of Mechanical, Electrical, and Plumbing (MEP) Design with expert-led courses. Learn HVAC, fire safety, sustainable building strategies, and BIM applications to excel in the construction industry.

Know MoreSkills Required for an MEP Quantity Surveyor

To excel in this role, an MEP Quantity Surveyor must possess a unique blend of technical, analytical, and interpersonal skills. Here are the key skills required:

1. Technical Knowledge

- Having in-depth knowledge of MEP systems, as well as the methods used in construction and the materials concerned is necessary.

- It informs standards or even regulations, as well as best practices in the industry.

2. Financial Acumen

- Very good in number and practically analytical.

- Can work on estimating a cost accurately and budgeting for the same.

- It can handle and use cost management software and tools, such as CostX or BIM (Building Information Modeling).

3. Attention to Detail

- The MEP Quantity Surveyor must have an eye for detail: find the fine line between a contract, budget, and project plans and differentiate them from one another.

- It counts everything that is genuine in total amounts and in total in financial and technical documentation.

4. Communication Skills

- It can communicate effectively with clients, contractors, and team members.

- It must be able to write well and clear out convoluted financial data for easy understanding.

Get hands-on with our MEP Quantity Surveyor course – sign up for a free demo!

5. Problem-Solving Abilities

- Quick thinking and ahead of time to solve financial or contractual problems.

- It is the MEP Quantity Surveyor who can identify early most possible problems and develop effective solutions to them.

6. Time Management

- The task may be multiple, but it has to be effective to meet the short deadlines.

- Prioritizing tasks would ensure that project timelines are met.

7. Negotiation Skills

- Strong negotiation skills above the rest are essential to get better deals with contractors and suppliers.

- Such ability must also be present for amicably solving disputes when such arise.

8. Adaptability

- The construction industry is always changing, with technologies and methods coming up very quickly at short intervals.

- An MEP Quantity Surveyor will have to adapt and learn new tools and skills.

Conclusion

An MEP Quantity Surveyor plays a critical role in the success of any construction project involving mechanical, electrical, and plumbing systems. Their expertise in cost management, contract administration, and risk mitigation ensures that projects are completed on time, within budget, and to the highest quality standards. As the construction industry continues to evolve, the demand for skilled MEP Quantity Surveyors is only expected to grow, making it a rewarding and impactful career choice.

Start a Rewarding Career in MEP! Free Demo Classes Here!

Whether you’re considering this career path or hiring an MEP Quantity Surveyor for your project, their contributions are invaluable. They not only ensure financial efficiency but also enhance the overall quality and sustainability of construction projects.

|

Engineering Upskilling Courses

|

| MEP Course |

| BIM Course |

| Quantity Surveyor Course |

| Structural Design Course |

| MEP QS Course |

Master MEP Design with Industry-Leading Training!

Gain in-depth knowledge of Mechanical, Electrical, and Plumbing (MEP) Design with expert-led courses. Learn HVAC, fire safety, sustainable building strategies, and BIM applications to excel in the construction industry.

Know MoreFrequently Asked Questions

1. What is the difference between a Quantity Surveyor and an MEP Quantity Surveyor?

Ans: A general Quantity Surveyor handles cost management for all aspects of a construction project, while an MEP Quantity Surveyor specializes in mechanical, electrical, and plumbing systems, which require specific technical knowledge.

2. What qualifications are needed to become an MEP Quantity Surveyor?

Ans: A degree in Quantity Surveying, Construction Management, or a related field is typically required. Additional certifications in MEP systems or cost management can be advantageous.

3. How does an MEP Quantity Surveyor contribute to sustainability in construction?

Ans: By optimizing resource use, suggesting energy-efficient materials, and implementing cost-effective solutions, an MEP Quantity Surveyor can help reduce the environmental impact of construction projects.

4. What software tools do MEP Quantity Surveyors use?

Ans: Common tools include cost estimation software like CostX, BIM (Building Information Modeling) software, and project management tools like Primavera or MS Project.

5. Is experience in MEP systems necessary to become an MEP Quantity Surveyor?

Ans: While not always mandatory, experience or knowledge of MEP systems is highly beneficial as it allows for better cost estimation, risk management, and value engineering.

6. What industries employ MEP Quantity Surveyors?

Ans: MEP Quantity Surveyors are employed in various industries, including construction, real estate, infrastructure development, and energy.

7. How does an MEP Quantity Surveyor add value to a project?

Ans: They add value by ensuring cost efficiency, minimizing risks, optimizing resources, and maintaining quality standards, ultimately contributing to the successful delivery of the project.