Table of Contents

Denim Stitching Techniques shape strong and stylish garments. They help beginners create neat and lasting seams. Denim fabric is thick and tightly woven. This makes simple stitching slightly challenging. Good techniques improve accuracy and stitch strength. They also reduce common sewing mistakes. Learning basics builds sewing confidence quickly. It prepares beginners for creative denim projects.

Denim garments are worn daily and frequently washed. Strong stitching helps them last much longer. Proper methods maintain comfort and perfect fit. They also enhance the overall garment appearance. Clear steps make learning simple and enjoyable. Practice improves speed, control, and stitch quality. Each project builds better sewing understanding. This guide supports confident denim stitching success.

Learn Advanced Designing & Boutique Skills with Experts. Join Now!

Introduction

Denim is a strong and versatile fabric. It is used for clothes and accessories. People love denim for style and durability. It suits casual and everyday wear. Learning denim stitching opens creative possibilities. Beginners can make durable handmade garments. It also helps with repairs and alterations. Proper knowledge gives clean stitching results.

Working with denim needs careful planning. Fabric thickness affects stitch quality. Wrong methods cause weak seams. This leads to fabric damage and discomfort. Correct techniques manage fabric layers smoothly. They reduce machine strain and thread breakage. This ensures long lasting garments. Good preparation improves stitching quality.

Beginners should learn basic denim sewing skills. Simple stitches build confidence and control. Practice improves hand coordination. It also teaches stitch behavior. Slow learning prevents frustration. Each project improves sewing knowledge. This makes advanced skills easier later. Patience supports steady improvement.

Denim projects give learning and satisfaction. They allow creative experiments. Beginners can sew skirts and bags. Each project teaches sewing lessons. Denim stitching builds discipline and creativity. It also improves problem solving skills. These skills support garment construction.

Benefits of learning denim stitching:

-

Builds strong sewing foundation

-

Improves stitch accuracy

-

Increases seam durability

-

Builds confidence with thick fabric

-

Encourages creative design

-

Supports clothing repair

-

Saves tailoring costs

-

Develops patience and focus

Understanding denim stitching builds sewing confidence. It helps beginners start without fear. Clear methods simplify complex work. With practice, denim sewing becomes enjoyable.

Why Denim Requires Special Stitching Techniques

Denim is thicker and more tightly woven than most fabrics. This makes regular stitching weak and unreliable. Special stitching techniques improve seam strength and appearance. They help denim garments handle daily movement and stress.

Denim also has multiple fabric layers in areas like pockets and hems. These layers make sewing more difficult for machines and needles. Special methods control fabric movement and reduce stitching errors. This ensures better durability and professional finishing.

Key reasons special stitching is needed:

-

Thick fabric resists needle penetration

-

Dense weave increases thread tension

-

High-stress areas need reinforcement

-

Visible stitching affects garment design

-

Multiple layers cause feeding problems

-

Strong seams increase garment life

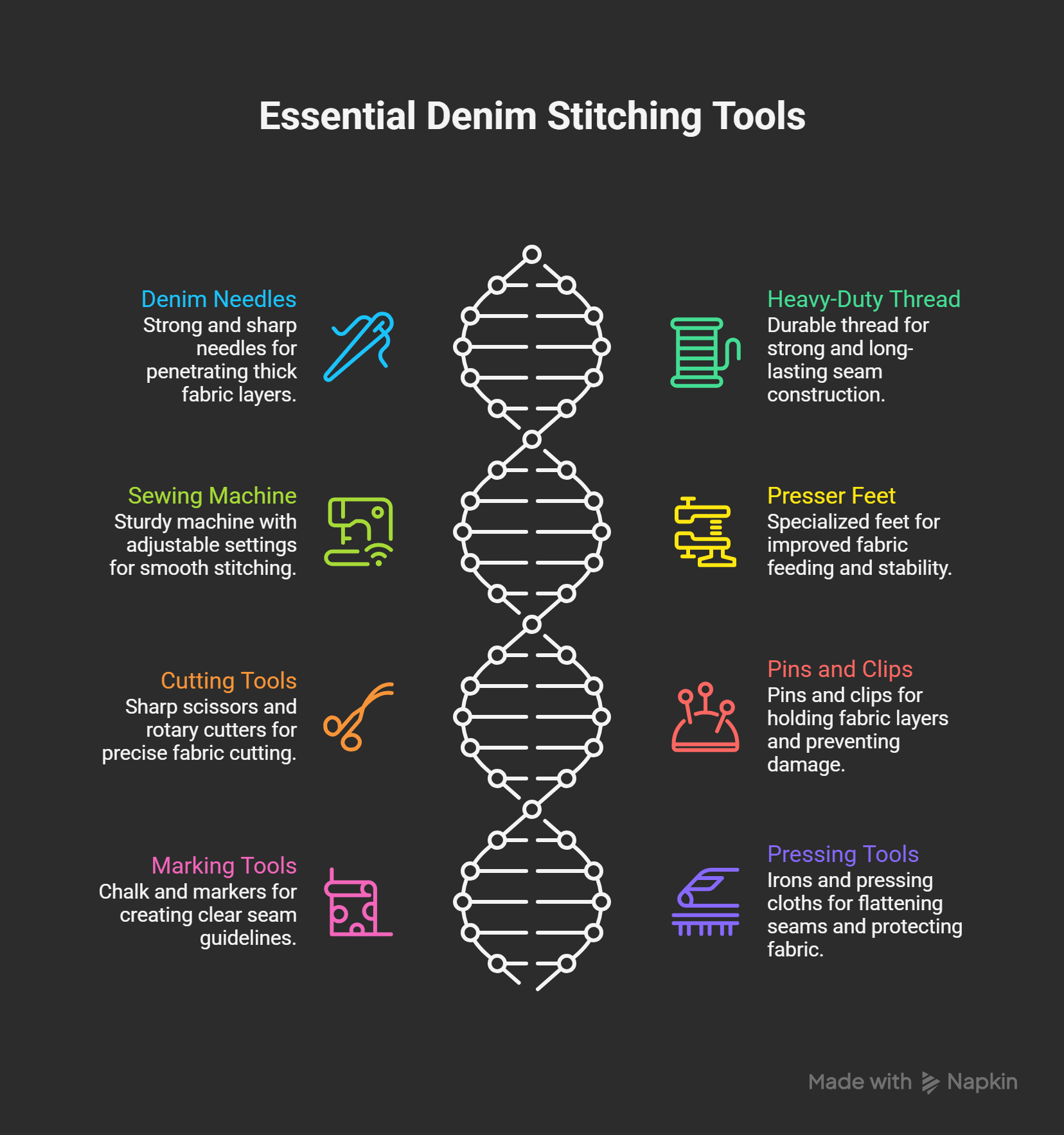

Essential Tools and Materials for Denim Stitching

Master Fashion Designing and Create Your Signature Style

Unlock your creative potential with our expert-led Fashion Designing course. Build in-demand skills and step confidently into the world of fashion!

Begin Your Fashion Career Today!Frequently Asked Questions

Is denim stitching difficult for beginners?

Denim stitching may seem challenging at first due to fabric thickness and density. Beginners often find it harder than sewing lighter materials. However, with the right tools and techniques, denim becomes manageable. Learning basic stitching methods helps reduce early difficulties. Practice improves control, accuracy, and confidence. Starting with small projects makes learning easier. Gradual improvement helps avoid frustration. With patience, beginners can master denim stitching successfully.

What is the best needle for denim stitching?

Denim needles are best suited for stitching thick fabrics. These needles are stronger and sharper than regular needles. They penetrate dense fabric layers easily. Common sizes include 90/14, 100/16, and 110/18. Medium-weight denim usually needs a 90/14 needle. Heavy-weight denim requires larger needle sizes. Using correct needles prevents skipped stitches and breakage. This ensures smooth and consistent stitching results.

Which thread works best for denim sewing?

Polyester and cotton-wrapped polyester threads work best for denim. These threads provide high strength and durability. Heavy-duty thread supports thick fabric resistance. Topstitching thread adds decorative and bold seam appearance. Using strong thread prevents seam breakage. It also improves garment lifespan. Thread quality significantly affects stitch reliability. Choosing suitable thread ensures professional stitching results.

Can a regular sewing machine handle denim stitching?

Most regular sewing machines can stitch denim effectively. Correct needle, thread, and settings are essential. Machines with adjustable tension and stitch length perform better. Sewing slowly helps prevent machine strain. Thick layers require careful handling and patience. Heavy-duty machines provide additional comfort. However, beginners can succeed using standard machines. Proper technique makes denim stitching smooth and manageable.

Why does my sewing needle keep breaking on denim?

Needle breakage often occurs due to incorrect needle size. Thick fabric layers increase resistance. Sewing too fast also causes needle stress. Incorrect machine tension may lead to breakage. Using a denim needle reduces this problem. Slowing stitching speed improves needle control. Proper fabric guidance also prevents bending. Correct setup ensures smoother stitching performance.

How can I prevent skipped stitches while sewing denim?

Skipped stitches happen due to needle resistance and tension imbalance. Using sharp denim needles improves penetration. Balanced tension ensures smooth stitch formation. Increasing stitch length reduces fabric pulling. Sewing slowly improves needle accuracy. Maintaining consistent fabric pressure prevents stitch gaps. Regular machine maintenance supports smooth operation. Proper setup significantly reduces skipped stitches.

Should I prewash denim before stitching?

Yes, prewashing denim is highly recommended. Denim often shrinks after washing. Prewashing prevents size changes in finished garments. It also removes excess dye and chemicals. Clean fabric stitches more smoothly. Prewashing softens fibers for easier handling. This improves comfort and stitching consistency. It ensures better garment fit after construction.

What stitch length should I use for denim?

Longer stitch lengths work best for denim. Thick fabric layers require smooth needle movement. Short stitches may cause fabric puckering. Medium-weight denim suits 3.0 to 3.5 mm stitch length. Heavy denim benefits from 3.5 to 4.0 mm length. Correct length improves seam strength and appearance. Testing settings on scrap fabric ensures proper results.

How can I sew over thick denim seams easily?

Thick seams create uneven fabric levels. This makes needle penetration difficult. Using a hump jumper or folded scrap fabric helps. These tools level the presser foot height. Slowing sewing speed improves control. Hand-turning the wheel assists needle movement. Gentle fabric guidance prevents needle breakage. These methods ensure smooth seam crossing.

What are the most common mistakes in denim stitching?

Common mistakes include wrong needle choice and incorrect tension. Sewing too fast often causes uneven stitches. Ignoring fabric thickness leads to seam distortion. Skipping prewashing causes size issues later. Poor fabric handling results in crooked seams. Using dull cutting tools affects accuracy. Lack of pressing reduces garment finish quality. Awareness helps avoid these beginner mistakes.