Table of Contents

SAP MM is a core module in SAP ERP that is responsible for material management. This module requires individuals with good communication, analytical, and problem-solving skills. If you are going to face your SAP MM interview soon, you have come to the right place. In this article, we will discuss SAP MM interview questions and answers, we will go through basic, intermediate, and advanced levels of questions.

Join Entri’s SAP MM Training Course today!!

Introduction

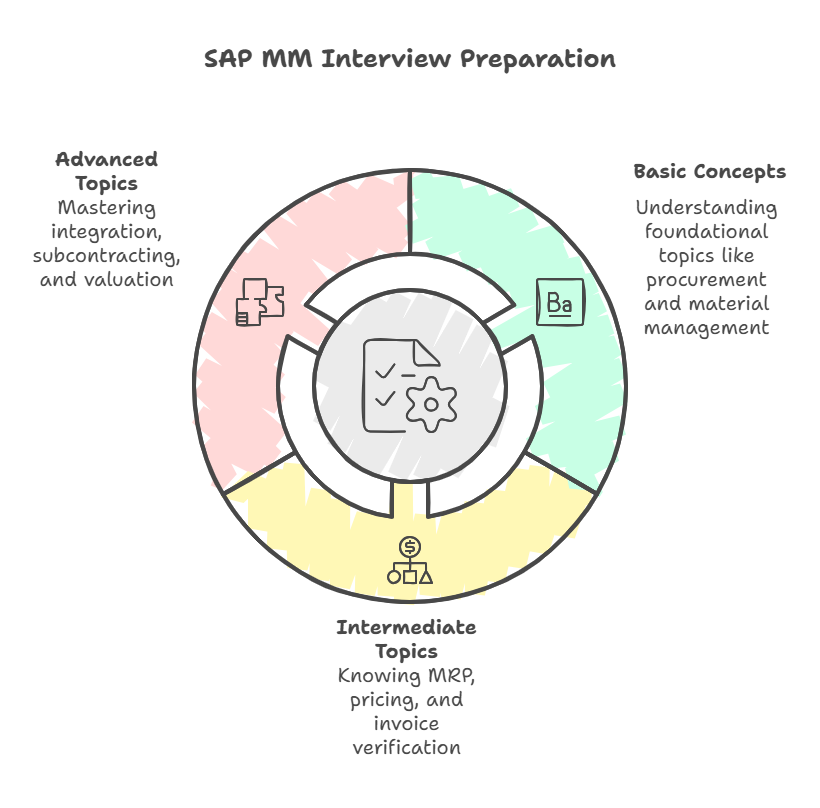

SAP MM (Materials Management) is a key module in SAP ERP that deals with procurement, inventory management, and material valuation. It plays a crucial role in ensuring an organization’s supply chain efficiency. If you’re preparing for an SAP MM interview, understanding the commonly asked questions can give you an edge. Preparing for an SAP MM interview requires:

Key Aspects Covered in SAP MM Interviews:

- Basic understanding of SAP MM concepts

- Procurement and inventory management processes

- Configuration and integration with other SAP modules

- Advanced troubleshooting and real-time scenarios

This guide categorizes questions into three levels: Basic, Intermediate, and Advanced, helping you navigate your interview with confidence.

SAP MM Interview Questions and Answers

SAP MM Interview Questions and Answers: Basic Level

1. What is SAP MM?

SAP MM (Materials Management) is a module in SAP ERP that manages procurement, inventory, and material valuation.

Key Features:

- Procurement process automation

- Inventory and stock management

- Material requirement planning (MRP)

- Invoice verification

2. Explain the procurement cycle in SAP MM.

The procurement cycle follows these steps:

- Purchase Requisition (PR) – Internal request for materials/services.

- Source Determination – Identifying suppliers.

- Purchase Order (PO) – Formal order to the supplier.

- Goods Receipt (GR) – Receiving the ordered materials.

- Invoice Verification – Checking supplier invoices.

- Payment Processing – Finalizing payments.

3. What are the different types of procurement?

- Standard Procurement – Purchasing goods from external vendors.

- Subcontracting – Sending raw materials to a vendor for assembly.

- Stock Transfer – Moving materials between company locations.

- Third-Party Procurement – Ordering materials from a vendor and delivering directly to the customer.

4. What is a Purchase Requisition (PR)?

A PR is an internal document requesting procurement of materials or services.

Components of a PR:

- Material/service details.

- Required quantity and delivery date.

- Preferred vendor (if applicable).

- Department making the request.

Process:

- Created by the requesting department.

- Sent for approval.

- Converted into a Purchase Order (PO) after approval.

5. Define Purchase Order (PO).

A Purchase Order (PO) is a formal document issued to a supplier requesting the supply of goods or services. It acts as a legally binding contract between the buyer and the seller. The key elements of a PO include:

- PO Number (Unique Identifier)

- Vendor Details

- Material Description

- Quantity and Unit Price

- Terms and Conditions

- Payment Terms

A PO can be created manually or automatically from an approved PR, and it helps maintain transparency and control over procurement transactions.

6. What are the different types of stock in SAP MM?

- Unrestricted Stock – Available for use.

- Blocked Stock – Cannot be used or sold.

- Quality Inspection Stock – Awaiting quality check.

- Restricted Stock – Reserved for a specific purpose.

7. What is the difference between a Purchase Order and a Scheduling Agreement?

| Aspect | Purchase Order | Scheduling Agreement |

|---|---|---|

| Used for | One-time procurement | Recurring procurement |

| Document type | PO | SA |

| Flexibility | Can change frequently | Fixed schedule |

8. What is the purpose of Material Master in SAP MM?

The Material Master contains detailed information about materials used in an organization, including:

- Material type

- Unit of measure

- Storage location

- Valuation class

Join Entri’s SAP MM Training Course today!!

SAP MM Interview Questions and Answers: Intermediate Level

9. Explain the different types of MRP (Material Requirement Planning) in SAP MM.

- MRP 1 – Defines planning strategy.

- MRP 2 – Includes procurement type and lot-sizing.

- MRP 3 – Contains forecasting details.

- MRP 4 – Includes storage and production details.

10. What is a Movement Type in SAP MM?

Movement Types define the type of material movement, such as:

- goods receipt

- issue

- stock transfer

| Movement Type | Description |

|---|---|

| 101 | Goods Receipt (GR) |

| 201 | Goods Issue (GI) |

| 301 | Stock Transfer |

11. What is the difference between Reservation and Requisition?

| Aspect | Reservation | Requisition |

|---|---|---|

| Purpose | Holds stock for future use | Requests stock procurement |

| Creation | Created for planned stock movements | Created when materials are required |

| Effect on Inventory | Reserves stock without procurement | May result in a purchase order |

12. What is the Pricing Procedure in SAP MM?

The pricing procedure determines how the system calculates the final price in a PO. It includes:

- Condition Types (e.g., Discounts, Freight, Taxes)

- Access Sequences

- Calculation Schema

13. What are Release Strategies in SAP MM?

A release strategy is a predefined approval workflow for PRs and POs. It ensures that procurement activities follow an organization’s hierarchy and authorization levels.

- Types of Release Strategies:

- PR Release Strategy

- PO Release Strategy

- Approval Criteria:

- Document type

- Value limits

- Purchasing group

14. What is an Invoice Verification Process?

Invoice verification is the process of matching an invoice with the PO and GR before making payments. The steps involved include:

- Invoice Entry

- Matching with PO and GR

- Payment Processing

15. Explain Automatic Account Determination in SAP MM.

This process assigns GL accounts to different transactions based on predefined rules. It ensures accurate financial postings without manual intervention by using:

- Valuation Class

- Account Category Reference

- Transaction Keys

16. What is the difference between GR-Based and Invoice-Based Goods Receipt?

| Type | Description |

| GR-Based Receipt | Payment is processed only after the goods are received. |

| Invoice-Based Receipt | Payment is made before receiving the goods, based on trust. |

17. How does SAP MM integrate with other modules?

SAP MM interacts with multiple modules to streamline business processes.

| Module | Integration with MM |

| FI (Financial Accounting) | Helps in invoice verification and payment processing. |

| SD (Sales & Distribution) | Links with order processing and deliveries. |

| PP (Production Planning) | Supports material requirement planning. |

18. Explain Consignment Process in SAP MM.

Consignment allows businesses to store vendor-owned stock without upfront purchase.

Process:

- Vendor supplies stock to the company’s premises.

- Stock remains vendor-owned until consumed.

- Payment is made only for consumed stock.

Key Benefits:

- Reduces inventory holding costs.

- Improves cash flow management.

SAP MM Interview Questions and Answers: Advanced Level

19. What is External Service Procurement?

External service procurement refers to the acquisition of services rather than materials. Examples include:

- IT Services

- Facility Maintenance

- Consulting

The process involves:

- Creating a Service Entry Sheet

- Approving the service

- Making payments

20. What is a Blanket Purchase Order?

A Blanket Purchase Order (BPO) is a long-term agreement that allows multiple purchases over a period without creating new POs for each order. It is useful for recurring purchases such as office supplies or maintenance services.

21. Explain Subcontracting in SAP MM.

Subcontracting is outsourcing manufacturing or processing tasks while retaining material ownership.

Process:

- Create a subcontracting Purchase Order.

- Send raw materials to the subcontractor.

- Receive finished goods from the vendor.

- Perform invoice verification and payment.

Advantages:

- Reduces in-house production load.

- Leverages vendor expertise.

22. What are the different Inventory Valuation Methods in SAP MM?

| Method | Description |

| Standard Price Valuation | Fixed cost per unit is maintained. |

| Moving Average Price Valuation | Price updates based on recent transactions. |

23. What is the function of Split Valuation in SAP MM?

Split valuation allows the same material to have different valuations based on:

- Procurement Type (In-house vs. External)

- Quality (Grade A, B, C)

- Location (Different storage locations)

This feature helps companies manage material costs effectively based on varying conditions.

24. What are the steps in Physical Inventory Process in SAP MM?

The physical inventory process ensures stock accuracy in SAP MM.

Steps:

- Create Physical Inventory Document: Initiates stock verification.

- Record Count: Warehouse personnel perform physical stock counting.

- Compare System vs. Actual Count: Identify discrepancies.

- Adjust Inventory Records: Update SAP stock levels accordingly.

Types of Physical Inventory:

- Periodic Inventory: Conducted at specific intervals.

- Cycle Counting: Regular checks on selected materials.

- Continuous Inventory: Ongoing stock verification.

Join Entri’s SAP MM Training Course today!!

Master SAP with Expert-Led Courses

Unlock your potential with our comprehensive SAP courses! Learn essential modules like SAP MM (Materials Management), SAP SD (Sales and Distribution), and SAP FICO (Financial Accounting and Controlling) from industry experts.

Know MoreConclusion

SAP MM is a crucial module in SAP ERP, handling procurement, inventory, and material valuation. Preparing for an SAP MM interview requires:

- Understanding basic concepts like:

- procurement

- material management

- Knowing intermediate topics like:

- MRP

- pricing

- invoice verification

- Mastering advanced topics like:

- integration

- subcontracting

- valuation

By studying these SAP MM interview questions and answers, and practicing real-world scenarios, you’ll increase your chances of acing your interview and securing your desired role in SAP MM.

Master SAP with Expert-Led Courses

Unlock your potential with our comprehensive SAP courses! Learn essential modules like SAP MM (Materials Management), SAP SD (Sales and Distribution), and SAP FICO (Financial Accounting and Controlling) from industry experts.

Know MoreFrequently Asked Questions

What is SAP MM, and why is it important?

SAP MM (Materials Management) is a module in SAP ERP that handles procurement, inventory, and material valuation. It ensures a smooth supply chain by automating purchasing, stock management, and invoice verification. SAP MM integrates with other modules like FI, SD, and PP for seamless business operations. It helps organizations maintain optimal inventory levels, reduce costs, and improve efficiency. The module supports different procurement processes, including standard, subcontracting, and third-party procurement.

How does SAP MM support procurement processes?

SAP MM streamlines procurement by automating purchase requisitions, orders, goods receipts, and invoice verifications. The module enables tracking of vendor performance and ensures compliance with business rules. It supports different procurement types, including standard, consignment, subcontracting, and stock transfers. Purchase orders can be generated manually or automatically based on predefined rules. This automation reduces errors, speeds up procurement cycles, and improves cost control.

What is the difference between a Purchase Requisition and a Purchase Order?

A Purchase Requisition (PR) is an internal document requesting material or service procurement, while a Purchase Order (PO) is a formal contract issued to a supplier. PRs are created within departments and require approval before processing into a PO. POs include details like quantity, price, delivery terms, and payment conditions. POs legally bind the supplier and buyer, ensuring order fulfillment. PRs help in planning, while POs execute purchases

How does SAP MM handle inventory management?

SAP MM tracks stock movements in real time through goods receipts, issues, and transfers. It categorizes inventory into unrestricted, blocked, quality inspection, and reserved stock. The system automates stock valuation, reducing discrepancies and ensuring accurate reporting. Physical inventory processes, such as cycle counting and periodic checks, help maintain accuracy. SAP MM prevents stock shortages or overstocking, optimizing material flow.

What is a Goods Receipt (GR) and an Invoice Verification in SAP MM?

A Goods Receipt (GR) records the arrival of materials from a vendor, updating stock levels in SAP MM. It ensures the received quantity matches the purchase order and triggers quality inspections if required. Invoice verification matches the invoice, PO, and GR to prevent overpayments. If discrepancies arise, the system flags them for review before payment processing. GR and invoice verification are essential to ensuring accurate procurement and financial transactions.

How does SAP MM integrate with other SAP modules?

SAP MM integrates with FI (Financial Accounting) for invoice processing and cost tracking. It connects with SD (Sales and Distribution) for sales order processing and deliveries. MM and PP (Production Planning) work together to ensure material availability for manufacturing. Integration with WM (Warehouse Management) enhances stock handling and storage efficiency. These integrations provide end-to-end supply chain visibility and automation.

What are Movement Types in SAP MM, and why are they important?

Movement Types define different types of stock transactions, such as receipts, issues, and transfers. Common movement types include 101 (Goods Receipt), 201 (Goods Issue to Cost Center), and 301 (Stock Transfer between Plants). They determine whether stock increases, decreases, or moves within the system. Movement types also affect financial postings and valuation. Using the correct movement type ensures accurate inventory tracking and accounting.

What is the role of Material Requirement Planning (MRP) in SAP MM?

MRP ensures materials are available for production and customer orders by analyzing demand and supply. It calculates procurement and replenishment needs based on factors like inventory levels, lead times, and open purchase orders. MRP runs generate planned orders or purchase requisitions automatically. It helps avoid stockouts or excessive inventory, optimizing working capital. Effective MRP execution enhances production efficiency and supply chain stability.

What is the significance of Split Valuation in SAP MM?

Split Valuation allows different valuation methods for the same material based on factors like procurement type, location, or batch. It helps businesses manage cost variations by maintaining different price records for materials with differing quality, origin, or supplier. For example, in-house produced and externally purchased goods can have separate valuations. This ensures accurate financial reporting and better cost control. Companies use split valuation for precise material costing in complex procurement scenarios.

What are Release Strategies in SAP MM?

A Release Strategy is an approval workflow for purchase requisitions and purchase orders. It ensures that procurement documents follow predefined authorization rules before processing. Approvals depend on factors like document value, purchasing group, and material type. Release strategies help organizations maintain control over spending and prevent unauthorized purchases. They automate the approval process, improving procurement transparency and compliance.