Table of Contents

Six Sigma has its origins in a 19th-century mathematical theory, but it entered the mainstream business world in the 1980s thanks to the efforts of an engineer at Motorola. Six Sigma has evolved over the years into what is now recognized as one of the most effective methodologies for enhancing customer satisfaction and business operations.

Looking for a Data science and Machine learning Career? Explore Here!!

What is Six Sigma?

The Six Sigma methodology gives firms the tools they need to become more adept at running their operations. With this improvement in performance and decrease in process variance, it is feasible to lower failure rates, boost employee morale, and enhance the quality of goods or services, all of which help to raise profitability.

By lowering the likelihood of error, the Six Sigma collection of management tools and procedures is intended to increase the capability of the business process. Six sigma is a data-driven strategy that employs statistical methods for defect eradication, defect reduction, and revenue growth.

Six Sigma is a statistical phrase derived from the bell curve, where sigma denotes the standard deviation from the centre. Hence, a process with six sigma’s will produce a very low defect rate. A flaw is considered to exist when a business procedure or product fails. A process is deemed efficient if it results in 3.4 or fewer faults for every million possibilities.

How Six Sigma Started

1: Which of the following algorithms is most suitable for classification tasks?

Carl Fredrich Gauss, a German mathematician and physicist, devised the bell curve in the nineteenth century. The bell curve established the idea of what a normal distribution looks like, which led to its early use as a tool for identifying flaws and faults in a process.

According to “The Complete Business Process Handbook: Body of Knowledge From Process Modeling to BPM Vol. 1” by Mark von Rosing, August-Wilhelm Scheer, and Henrik von Scheel, American physicist, engineer, and statistician Walter Shewhart built on this theory and established that “sigma imply where a process requires modification” in the 1920s.

According to “Six Sigma” by Mikel Harry and Richard Schroeder, Motorola used the Six Sigma methodology to improve product consistency during the 1980s, which helped spread the concept.

Bill Smith, a Motorola engineer, later rose to prominence as one of the founders of contemporary Six Sigma, developing many of the approaches that are being used today in the field in the late 1980s. Other management improvement techniques of the day, such as Total Quality Management and Zero Defects, have an influence on the system but are not similar to it.

Ready to take your data science skills to the next level? Sign up for a free demo today!

🚀 Start Coding Today! Enroll Now with Easy EMI Options. 💳✨

Equip yourself with in-demand skills to land top-tier roles in the data-driven world.

Start Learning Now with EMI OptionsMethodologies of Six Sigma

According to the 2005 book “JURAN Institute Six Sigma Breakthrough and Beyond” by Joseph A. De Feo and William Barnard, there are two main methodologies to Six Sigma, both of which are made up of five sections.

DMAIC:

The DMAIC method is mostly employed to enhance current business processes. The symbols represent:

- Describe the issue and the project objectives.

- Measure each component of the present process in detail.

- Analyse data to identify process flaws at their core, among other things.

- Improve the procedure

- Control how the procedure is carried out in the future

DMADV:

The DMADV approach is frequently employed to develop new procedures, goods, or services. The symbols represent:

- Define design criteria that are in line with the goals of the product or process.

- Measure and identify essential product or process attributes.

- Analyse the data and look for potential causes of errors.

- Design modifications that remove the cause of flaws or errors

- Verify if the design meets the specifications.

Principles of Six Sigma

Delivering nearly perfect products and services for company transformation to maximize customer satisfaction is the straightforward objective of the Six Sigma approach (CX).

Six Sigma is built on the following five guiding principles:

Focus on the Customer

The idea that “the client is king” is the foundation for this. The main objective is to benefit the consumer as much as possible. To do this, a company must comprehend its clientele—their wants, needs, and factors that influence loyalty or sales. To do this, the quality standard must be established according to what the consumer or market expects.

Measure the Value Stream and Find Your Problem

To identify waste regions in a process, map out the processes. Collect information to identify the precise issue that needs to be fixed or modified. Have standardized data collection methods and have goals for data collection that are clearly specified, including the data to be collected, the reason for the data collection, the expected insights, and the assurance of measurement accuracy. Determine whether the data is assisting in achieving the goals, whether it needs to be adjusted, and whether more information needs to be gathered. Determine the issue. Ask inquiries to identify the underlying issue.

Get Rid of the Junk

Once the issue has been located, modify the procedure to remove variation and consequently flaws. Process operations that don’t increase the value to the consumer should be eliminated. Tools are utilized to help find the outliers and problem areas if the value stream is unable to indicate where the issue is. Simplify processes to ensure efficiency and quality. In the end, bottlenecks in the process are eliminated by getting rid of the aforementioned garbage.

Keep the Ball Rolling

Include all interested parties. Establish a disciplined approach where your team contributes and works together to solve problems using their varied knowledge.

The application of Six Sigma procedures can have a significant impact on a business, so the team must be knowledgeable about the guiding principles and methodologies. As a result, to lower the risk of project or re-design failures and guarantee that the process operates at peak efficiency, specialist training and knowledge are needed.

Ensure a Flexible and Responsive Ecosystem

Change and transformation in the business world are at the heart of Six Sigma. When a flawed or ineffective process is eliminated, it necessitates a shift in work procedures and employee behavior. A strong culture of adaptability and responsiveness to adjustments in protocols helps guarantee efficient project execution. Processes should be created for quick and seamless adoption in order to make it easier for the concerned departments and employees to adapt to change. In the end, the business that keeps a close eye on the data, regularly reviews the bottom line, and modifies its procedures as needed can acquire a competitive edge.

Looking for a Data Science Career? Explore Here!

Six Sigma Techniques

To accomplish the desired output, the Six Sigma approach employs a combination of statistics and data analysis tools, such as process mapping and design, as well as established qualitative and quantitative techniques.

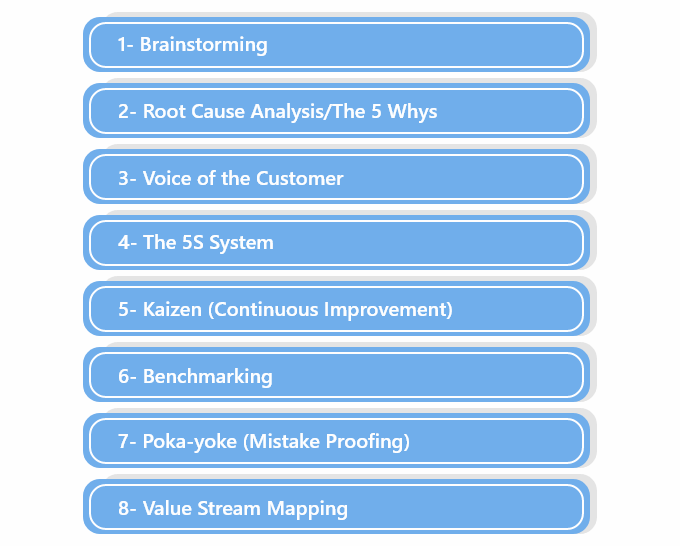

Brainstorming

Brainstorming is the central process of any problem-solving approach, and it is frequently used in the DMAIC methodology’s “enhance” phase. Before someone uses any tools, it is a prerequisite process. Brainstorming is the process of vigorous, unstructured group talks where ideas are tossed around and original solutions to problems are developed. An open session is facilitated by a facilitator, who is often the lead Black Belt or Green Belt.

Root Cause Analysis/The 5 Whys

This method is utilized in the “analyze” phase of the DMAIC cycle to help get to the fundamental cause of the problems under discussion.

With the “5 Whys” method, the “why” question is asked repeatedly until it reaches the fundamental problem. Although “five” is a general guideline, the actual number of questions can be higher or lower, depending on what is necessary to get clarity.

Voice of the Customer

This is the procedure for gathering the “voice of the customer” or consumer feedback, either internally or externally. The technique aims to provide the greatest goods and services to the client. Via direct and indirect means, it catches the customer’s shifting demands. The DMAIC method’s “define” phase is when the voice of the customer technique is typically utilized to further identify the issue that needs to be solved.

The 5S System

This method is based on a Japanese idea of workplace energy. The 5S System aims to eliminate waste and bottlenecks caused by ineffective tools, resources, or equipment in the workplace. Seiri (Sort), Seiton (Put In Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke are the five steps that are employed (Sustain).

Kaizen (Continuous Improvement)

A potent tactic that drives a constant engine for corporate improvement is the kaizen technique. Continuous monitoring, improvement identification, and implementation are all part of the approach. This method is very beneficial for the manufacturing industry. Waste is decreased because to constant, collective improvements, and anytime even the smallest inefficiency is noticed, something is changed right away.

Benchmarking

The method of benchmarking uses a predetermined unit of measurement. To get an unbiased assessment of the current situation, it requires establishing comparisons with other companies. Internal benchmarking, functional benchmarking, or comparing similar work areas or functions with industry leaders are a few examples of how benchmarking can be used to compare critical business processes or departments (competitive benchmarking).

Poka-yoke (Mistake Proofing)

The name of this strategy, which means “to avoid errors” in Japanese, refers to reducing the likelihood that mistakes will be made. Employees use the poka-yoke approach to identify and correct human faults and inefficiencies during the manufacturing process.

Value Stream Mapping

To plan a future project, the value stream mapping technique maps the existing flow of materials and information. The goal is to streamline processes and eliminate waste and inefficiencies in the value stream. It lists three separate garbage removal operations as well as seven different waste types.

🚀 Start Coding Today! Enroll Now with Easy EMI Options. 💳✨

Equip yourself with in-demand skills to land top-tier roles in the data-driven world.

Start Learning Now with EMI OptionsBenefits of Six Sigma

Will decrease waste

The goal of the Six Sigma philosophy is to assist you and your business in streamlining procedures to reduce overall waste. You may identify and address wasteful areas in your organization with the help of the special methodology, which will help you save time, money, and resources.

Will increase efficiency

Six Sigma helps you further maximize efficient processes in addition to assisting with waste reduction. You can increase the effectiveness of your present business operations by utilizing resources to the fullest extent with the help of formal training.

Will reduce errors

Six Sigma gives both process and quality equal consideration. Making your product perfect the first time is the best approach to save you time and money because you can’t “undo” a production work.

Will reduce company’s legal risk

The same procedure that saves you money will also shield you against conceivable legal costs, which may sound too good to be true. Using this methodology can help you stay inside international compliance standards due to Six Sigma’s commitment to quality.

Can apply it to any industry

The fact that Six Sigma may be used in almost any business is one of its best features. Anything from higher education to manufacturing to healthcare—you name it! Any business can use the methods and resources they learn during training to cut expenses and boost revenue.

Will make more money

Most Black Belt qualified professionals report earnings of above 100,000, with typical Six Sigma certified professionals experiencing a 19% salary boost per level! (source).

Get hands-on with our data science and machine learning course – sign up for a free demo!